- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

What are the Weight and Strength Characteristics of Gr7 Titanium Wire?

2025-03-20 15:36:23

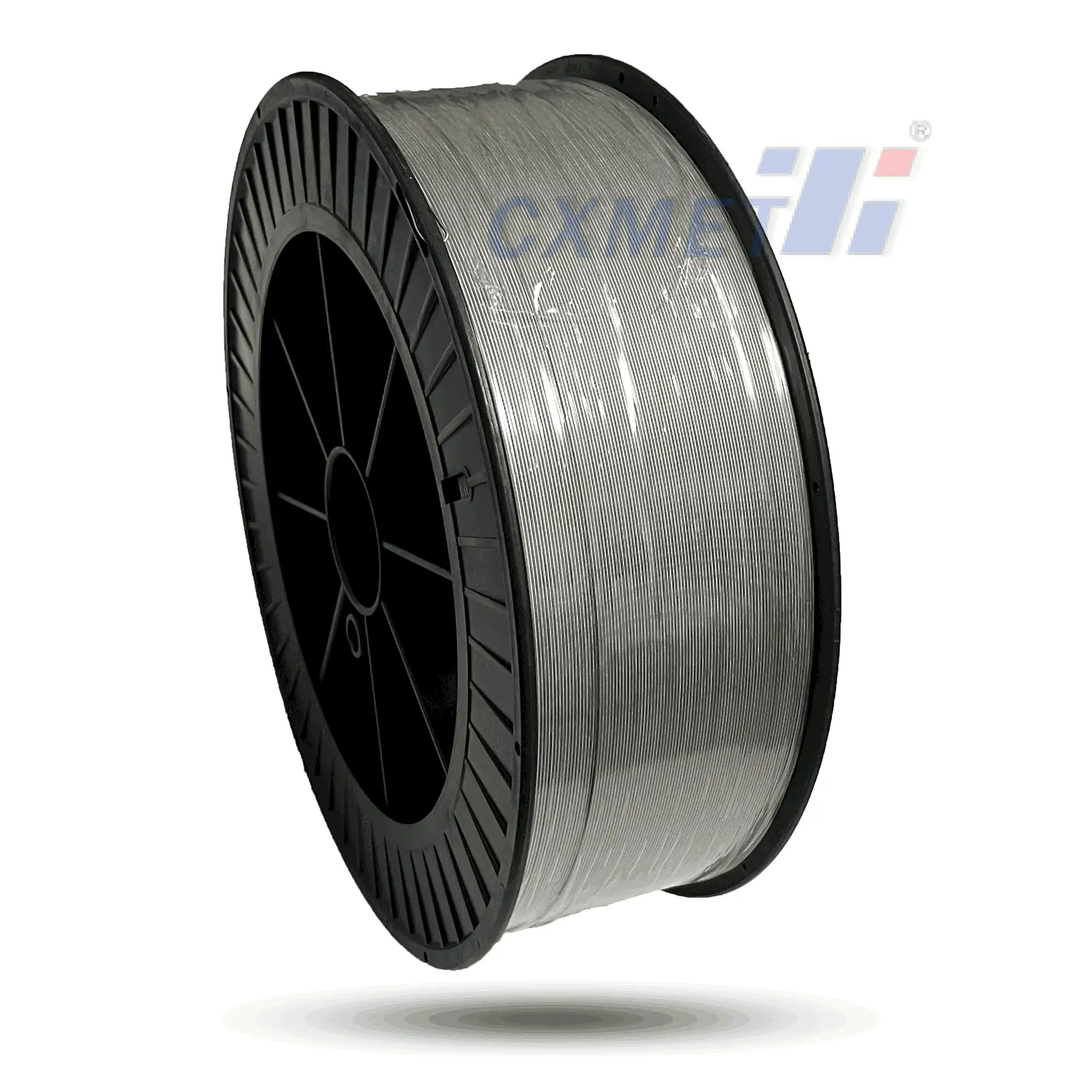

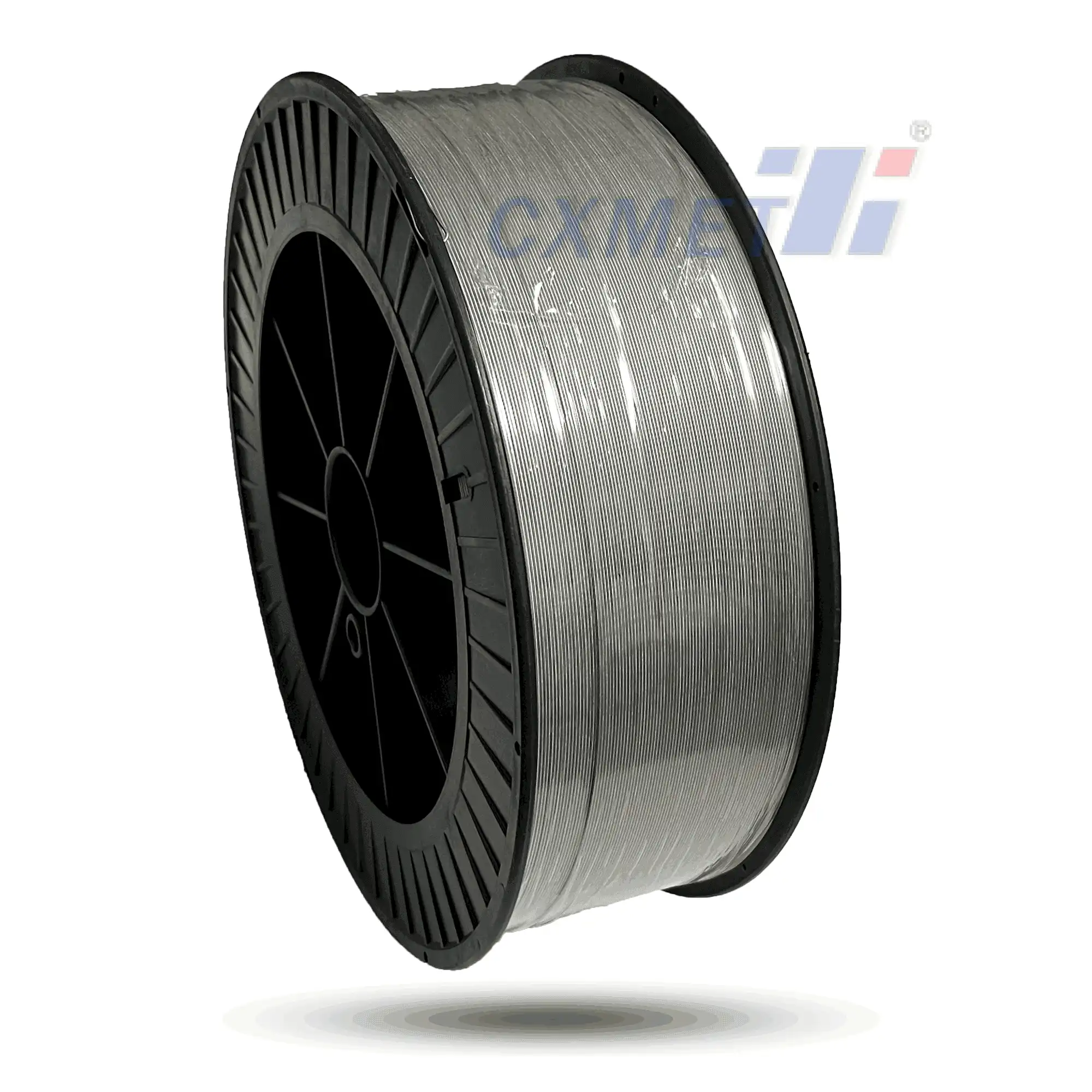

Grade 7 titanium wire, also known as Gr7 titanium wire, is a high-performance material known for its exceptional strength-to-weight ratio and corrosion resistance. This alloy combines the inherent properties of titanium with the added benefits of palladium, resulting in a wire that offers superior performance in various applications. In this blog post, we'll explore the weight and strength characteristics of Gr7 titanium wire, as well as its unique properties and applications.

|

1 |

|

How does Gr7 titanium wire compare to other titanium grades in terms of strength?

Grade 7 titanium wire is part of the commercially pure (CP) titanium family, specifically designed for enhanced corrosion resistance. When comparing Gr7 titanium wire to other titanium grades, it's essential to consider its unique composition and properties.

Gr7 titanium contains a small amount of palladium (0.12-0.25%), which significantly improves its corrosion resistance, especially in reducing acid environments. This addition of palladium sets Gr7 apart from other CP titanium grades like Gr1, Gr2, and Gr4.

In terms of strength, Gr7 titanium wire exhibits properties similar to Grade 2 titanium. It has a minimum tensile strength of 345 MPa (50 ksi) and a yield strength of 275 MPa (40 ksi). While these values are lower than those of higher-strength titanium alloys like Ti-6Al-4V (Grade 5), Gr7 titanium wire offers a excellent balance between strength and corrosion resistance.

The strength characteristics of Gr7 titanium wire make it suitable for various applications where moderate strength and exceptional corrosion resistance are required. Some key points to consider when comparing Gr7 titanium wire to other grades include:

- Corrosion resistance: Gr7 outperforms most other titanium grades in corrosion resistance, especially in reducing acid environments.

- Strength-to-weight ratio: While not as strong as some titanium alloys, Gr7 still offers an excellent strength-to-weight ratio compared to many other metals.

- Ductility: Gr7 titanium wire exhibits good ductility, making it suitable for applications that require forming or shaping.

- Weldability: Like other CP titanium grades, Gr7 has excellent weldability, allowing for easy integration into various structures and components.

When selecting a titanium grade for a specific application, it's crucial to consider the balance between strength, corrosion resistance, and other properties. While Gr7 may not be the strongest titanium grade available, its unique combination of properties makes it an excellent choice for many demanding environments and applications.

What is the density of Gr7 titanium wire and how does it affect its weight?

The density of Gr7 titanium wire is a crucial factor in understanding its weight characteristics and how it compares to other materials. Gr7 titanium, like other commercially pure titanium grades, has a density of approximately 4.51 g/cm³ (0.163 lb/in³). This density is significantly lower than that of many other metals commonly used in industrial applications, such as stainless steel (approximately 8.0 g/cm³) or nickel alloys (around 8.9 g/cm³).

The low density of Gr7 titanium wire directly affects its weight, making it an attractive option for applications where weight reduction is crucial. Some key points to consider regarding the density and weight of Gr7 titanium wire include:

- Lightweight nature: The low density of Gr7 titanium wire results in a lightweight material, which is beneficial in aerospace, automotive, and marine applications where weight savings are critical.

- Strength-to-weight ratio: Despite its lower density, Gr7 titanium wire maintains a high strength-to-weight ratio, offering excellent mechanical properties without adding significant weight to structures or components.

- Energy efficiency: In applications where moving parts are involved, the use of lightweight Gr7 titanium wire can contribute to improved energy efficiency and reduced fuel consumption.

- Handling and installation: The lighter weight of Gr7 titanium wire can make it easier to handle and install, potentially reducing labor costs and improving worker safety in certain applications.

To put the weight advantage of Gr7 titanium wire into perspective, consider the following comparison:

For a given volume of wire, Gr7 titanium would weigh approximately:

- 56% less than stainless steel

- 49% less than nickel alloys

- 37% less than copper

This significant weight reduction can lead to substantial benefits in various applications, such as:

- Aerospace: Lighter components result in improved fuel efficiency and increased payload capacity for aircraft and spacecraft.

- Automotive: Weight reduction in vehicles contributes to better fuel economy and improved performance.

- Marine: Lightweight materials in marine applications can enhance vessel speed, fuel efficiency, and maneuverability.

- Medical devices: In implants and surgical instruments, the lightweight nature of Gr7 titanium wire can improve patient comfort and ease of use for medical professionals.

When considering the use of Gr7 titanium wire in a specific application, it's essential to evaluate the weight savings potential and how it may impact the overall performance and efficiency of the system. The combination of low weight and high strength makes Gr7 titanium wire an excellent choice for many demanding applications where both factors are critical.

|

|

|

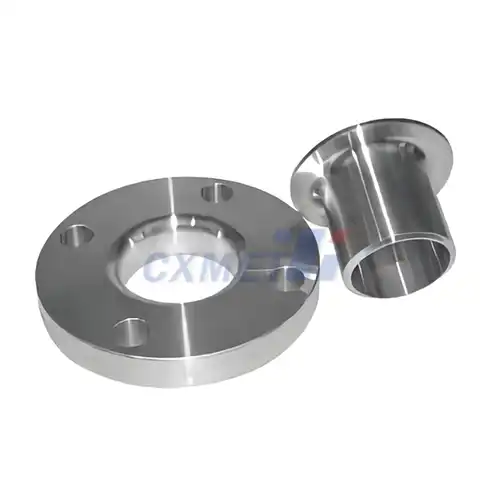

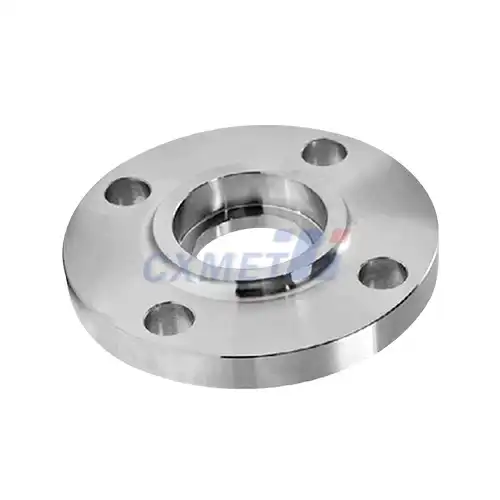

What are the main applications of Gr7 titanium wire due to its weight and strength properties?

The unique combination of weight and strength properties of Gr7 titanium wire makes it an excellent choice for a wide range of applications across various industries. Its low density, high strength-to-weight ratio, and exceptional corrosion resistance contribute to its versatility and effectiveness in demanding environments. Some of the main applications of Gr7 titanium wire include:

- Chemical Processing Industry:

- Heat exchangers and condensers in corrosive environments

- Pumps and valves for handling aggressive chemicals

- Piping systems for transporting corrosive fluids

- Marine and Offshore Applications:

- Seawater handling systems

- Desalination plants

- Offshore oil and gas equipment exposed to saltwater

- Aerospace Industry:

- Aircraft components requiring high corrosion resistance

- Lightweight structural elements

- Fasteners and connectors in corrosive environments

- Medical Devices:

- Implants and prosthetics

- Surgical instruments

- Dental applications

- Energy Sector:

- Geothermal energy systems

- Nuclear power plant components

- Solar panel support structures in coastal areas

- Automotive Industry:

- Exhaust system components

- Lightweight structural elements in high-performance vehicles

- Corrosion-resistant fasteners and connectors

The weight and strength properties of Gr7 titanium wire contribute to its effectiveness in these applications in several ways:

- Corrosion Resistance: The addition of palladium in Gr7 titanium enhances its already excellent corrosion resistance, making it ideal for use in highly corrosive environments such as chemical processing plants, marine applications, and medical implants.

- Weight Reduction: The low density of Gr7 titanium wire allows for significant weight savings in applications where reducing overall weight is crucial, such as in aerospace and automotive industries.

- Strength-to-Weight Ratio: Despite its lightweight nature, Gr7 titanium wire maintains a high strength-to-weight ratio, making it suitable for applications that require both strength and weight reduction.

- Biocompatibility: The excellent biocompatibility of Gr7 titanium wire, combined with its strength and corrosion resistance, makes it an ideal material for medical implants and devices.

- Fatigue Resistance: Gr7 titanium wire exhibits good fatigue resistance, making it suitable for applications involving cyclic loading or stress.

- Temperature Resistance: With a high melting point and good mechanical properties at elevated temperatures, Gr7 titanium wire can be used in applications involving high-temperature environments.

When selecting Gr7 titanium wire for a specific application, it's important to consider not only its weight and strength characteristics but also its other properties, such as corrosion resistance, biocompatibility, and temperature resistance. The combination of these properties makes Gr7 titanium wire a versatile and high-performance material suitable for a wide range of demanding applications across various industries.

At SHAANXI CXMET TECHNOLOGY CO., LTD, we take pride in our extensive product range, which caters to diverse customer needs. Our company is equipped with outstanding production and processing capabilities, ensuring the high quality and precision of our products. We are committed to innovation and continuously strive to develop new products, keeping us at the forefront of our industry. With leading technological development capabilities, we are able to adapt and evolve in a rapidly changing market. Furthermore, we offer customized solutions to meet the specific requirements of our clients. If you are interested in our products or wish to learn more about the intricate details of our offerings, please do not hesitate to contact us at sales@cxmet.com. Our team is always ready to assist you.

|

|

|

|

References

- ASTM International. (2021). ASTM B348 - Standard Specification for Titanium and Titanium Alloy Bars and Billets.

- Leyens, C., & Peters, M. (Eds.). (2003). Titanium and titanium alloys: fundamentals and applications. John Wiley & Sons.

- Donachie, M. J. (2000). Titanium: a technical guide. ASM international.

- Boyer, R., Welsch, G., & Collings, E. W. (Eds.). (1994). Materials properties handbook: titanium alloys. ASM international.

- Lütjering, G., & Williams, J. C. (2007). Titanium (engineering materials and processes). Springer.

- Peters, M., Kumpfert, J., Ward, C. H., & Leyens, C. (2003). Titanium alloys for aerospace applications. Advanced engineering materials, 5(6), 419-427.

- Elias, C. N., Lima, J. H. C., Valiev, R., & Meyers, M. A. (2008). Biomedical applications of titanium and its alloys. Jom, 60(3), 46-49.

- Rack, H. J., & Qazi, J. I. (2006). Titanium alloys for biomedical applications. Materials Science and Engineering: C, 26(8), 1269-1277.

- Schutz, R. W., & Watkins, H. B. (1998). Recent developments in titanium alloy application in the energy industry. Materials Science and Engineering: A, 243(1-2), 305-315.

- Veiga, C., Davim, J. P., & Loureiro, A. J. R. (2012). Properties and applications of titanium alloys: a brief review. Reviews on advanced materials science, 32(2), 133-148.