- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

What Temperature Can a Zirconium Crucible Withstand?

2025-03-17 11:24:42

Zirconium crucibles are renowned for their exceptional heat resistance and ability to withstand extremely high temperatures. These crucibles are widely used in various industries, including metallurgy, materials science, and chemical processing, due to their remarkable thermal properties. The temperature that a zirconium crucible can withstand depends on several factors, including the purity of the zirconium, the specific alloy composition, and the manufacturing process. In general, zirconium crucibles can typically withstand temperatures ranging from 2000°C to 2400°C (3632°F to 4352°F), making them suitable for a wide range of high-temperature applications.

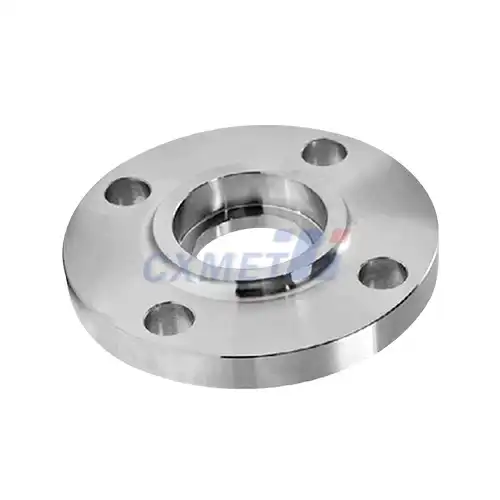

|

|

|

How does the purity of zirconium affect its melting point?

The virtue of zirconium plays a pivotal part in deciding its dissolving point and, subsequently, the greatest temperature a zirconium cauldron can withstand. Immaculate zirconium has a dissolving point of around 1855°C (3371°F), but this can shift depending on the nearness of debasements and alloying elements.

Higher immaculateness zirconium by and large shows a higher softening point and way better temperature resistance. This is since pollutions can shape lower dissolving point stages or eutectic compositions, which can decrease the in general temperature capability of the fabric. For case, the nearness of oxygen, nitrogen, or carbon can altogether influence the dissolving point and mechanical properties of zirconium.

Zirconium utilized in cauldron fabricating is ordinarily of tall virtue, frequently surpassing 99.5%. This tall virtue guarantees that the cauldrons can withstand temperatures near to the dissolving point of immaculate zirconium. Be that as it may, it's critical to note that the real temperature constrain of a zirconium cauldron is as a rule set underneath the dissolving point to keep up auxiliary judgment and avoid misshapening or disappointment amid use.

The prepare of decontaminating zirconium includes different steps, counting the expulsion of hafnium, which is actually display in zirconium metals. Hafnium has comparative chemical properties to zirconium but a lower dissolving point, so its expulsion is basic for creating high-temperature safe cauldrons. Progressed refinement methods, such as the van Arkel-de Boer handle or electrolytic refining, can create zirconium with purities surpassing 99.9%.

In expansion to virtue, the gem structure of zirconium too impacts its temperature resistance. Zirconium exists in two gem shapes: alpha (α) and beta (β). The move from α to β happens at roughly 863°C (1585°F). This stage change can influence the mechanical properties and temperature resistance of zirconium cauldrons, particularly when utilized in temperature ranges near to the move point.

What are the advantages of using zirconium crucibles in high-temperature applications?

Zirconium crucibles offer numerous advantages in high-temperature applications, making them a preferred choice in many industries. These advantages stem from zirconium's unique combination of properties, which include high melting point, excellent corrosion resistance, and low neutron absorption cross-section.

One of the primary advantages of zirconium crucibles is their exceptional temperature resistance. As mentioned earlier, they can withstand temperatures up to 2400°C, which surpasses many other refractory materials. This high-temperature capability allows for the processing of materials with extremely high melting points, such as certain ceramics, glasses, and metals.

Another significant advantage is zirconium's excellent corrosion resistance, particularly at elevated temperatures. Zirconium forms a stable, protective oxide layer (ZrO2) on its surface when exposed to oxygen at high temperatures. This oxide layer provides exceptional resistance to corrosion from molten metals, slags, and aggressive chemical environments. This property makes zirconium crucibles ideal for use in metal casting, glass melting, and chemical processing industries.

Zirconium crucibles also exhibit good thermal shock resistance, which is crucial in applications involving rapid temperature changes. This property allows for quicker heating and cooling cycles, improving process efficiency and reducing the risk of crucible failure due to thermal stress.

The low neutron absorption cross-section of zirconium makes it valuable in nuclear applications. Zirconium crucibles can be used in nuclear fuel processing and research reactors without significantly interfering with neutron flux. This property, combined with its high-temperature resistance and corrosion resistance, makes zirconium an essential material in the nuclear industry.

Furthermore, zirconium crucibles have excellent chemical inertness, which prevents contamination of the materials being processed. This is particularly important in applications requiring high purity, such as semiconductor manufacturing or materials research. The non-reactive nature of zirconium ensures that the crucible does not introduce unwanted elements or compounds into the melt.

Lastly, zirconium crucibles offer good dimensional stability at high temperatures. Unlike some other refractory materials that may soften or deform at extreme temperatures, zirconium crucibles maintain their shape and structural integrity. This property is crucial for maintaining consistent process conditions and ensuring the quality of the final product.

|

|

|

How does the manufacturing process impact the temperature resistance of zirconium crucibles?

The manufacturing process of zirconium crucibles plays a vital role in determining their temperature resistance and overall performance. Various techniques and considerations are employed to enhance the crucibles' ability to withstand extreme temperatures and maintain their structural integrity.

One of the key aspects of manufacturing high-temperature resistant zirconium crucibles is the selection of the starting material. As discussed earlier, high-purity zirconium is essential for achieving maximum temperature resistance. Manufacturers often use zirconium sponge or high-purity zirconium powder as the raw material. The purity of this starting material directly influences the final properties of the crucible.

The forming process is another critical factor in crucible manufacturing. Zirconium crucibles can be produced through various methods, including powder metallurgy, forging, and machining. Each method has its advantages and can impact the crucible's microstructure and, consequently, its temperature resistance.

Powder metallurgy techniques, such as hot isostatic pressing (HIP), are often employed to produce zirconium crucibles with high density and uniform microstructure. This process involves compacting zirconium powder under high pressure and temperature, resulting in a near-net-shape product with minimal porosity. The high density achieved through this method contributes to improved temperature resistance and mechanical properties.

Forging is another technique used to manufacture zirconium crucibles, particularly for larger sizes. This process involves shaping the zirconium through controlled deformation at elevated temperatures. Forging can improve the material's grain structure, leading to enhanced mechanical properties and temperature resistance. However, care must be taken to avoid introducing impurities during the forging process, which could negatively impact the crucible's performance.

Heat treatment is a crucial step in the manufacturing process that significantly affects the crucible's temperature resistance. Proper heat treatment can optimize the material's microstructure, relieve internal stresses, and improve overall performance. For zirconium crucibles, heat treatments are typically carried out in vacuum or inert atmospheres to prevent contamination and oxidation.

Surface treatment and coating technologies can also be applied to enhance the temperature resistance of zirconium crucibles. For instance, controlled oxidation can be used to create a protective zirconia (ZrO2) layer on the crucible's surface. This layer not only improves corrosion resistance but can also contribute to better temperature resistance in certain applications.

The design and geometry of the crucible also play a role in its temperature resistance. Manufacturers must consider factors such as wall thickness, shape, and thermal expansion characteristics to ensure optimal performance at high temperatures. Proper design can help distribute thermal stresses evenly and minimize the risk of failure during use.

Quality control throughout the manufacturing process is essential to ensure consistent temperature resistance. This includes rigorous testing of raw materials, in-process inspections, and final product evaluations. Advanced non-destructive testing methods, such as ultrasonic testing and X-ray inspection, are often employed to detect any defects or inconsistencies that could compromise the crucible's performance.

In conclusion, the temperature resistance of zirconium crucibles is a result of the complex interplay between material purity, manufacturing techniques, and design considerations. By carefully controlling these factors, manufacturers can produce crucibles capable of withstanding extreme temperatures and meeting the demanding requirements of various high-temperature applications. The continuous improvement in manufacturing processes and materials science continues to push the boundaries of what zirconium crucibles can achieve, opening up new possibilities for their use in advanced technologies and industrial processes.

At SHAANXI CXMET TECHNOLOGY CO., LTD, we take pride in our extensive product range, which caters to diverse customer needs. Our company is equipped with outstanding production and processing capabilities, ensuring the high quality and precision of our products. We are committed to innovation and continuously strive to develop new products, keeping us at the forefront of our industry. With leading technological development capabilities, we are able to adapt and evolve in a rapidly changing market. Furthermore, we offer customized solutions to meet the specific requirements of our clients. If you are interested in our products or wish to learn more about the intricate details of our offerings, please do not hesitate to contact us at sales@cxmet.com. Our team is always ready to assist you.

|

|

|

|

References

1. Schemel, J. H. (1977). ASTM manual on zirconium and hafnium. ASTM International.

2. Lustman, B., & Kerze, F. (1955). The metallurgy of zirconium. McGraw-Hill.

3. Ewing, R. C., & Weber, W. J. (2010). Actinide waste forms and radiation effects. In The Chemistry of the Actinide and Transactinide Elements (pp. 3813-3887). Springer.

4. Adamson, R. B., & Rudling, P. (2002). Dimensional stability of zirconium alloys. Journal of Nuclear Materials, 301(2-3), 131-143.

5. Banerjee, S., & Mukhopadhyay, P. (2007). Phase transformations: examples from titanium and zirconium alloys. Elsevier.

6. Kroll, W. J. (1940). The production of ductile titanium. Transactions of the Electrochemical Society, 78(1), 35-47.