- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

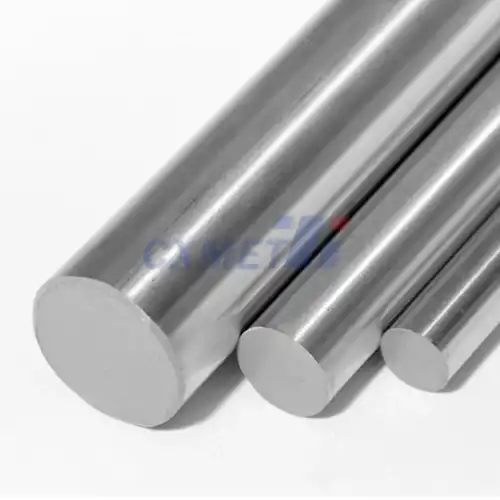

Grade 6 Titanium Bar

Brand: CXMET

Place Of Origin: China

Material: Titanium

Surface: Polished/Pickling

Type: Round

Shape: Round bar Standard: ASTM B348, ASTM F136, AMS 4920

Product Introduction

Grade 6 Titanium Bar is an alpha-beta titanium alloy composed primarily of titanium with 5 percent aluminum and 2.5 percent tin. This material is well-known for its excellent strength-to-weight ratio, outstanding corrosion resistance, and good weldability. Positioned between commercially pure titanium and higher strength alloys like Grade 5, Grade 6 titanium offers a balanced profile that serves multiple industries where reliability, structural integrity, and resistance to harsh environments are required.

As a leading manufacturer and global supplier, Shaanxi CXMET Technology Co., Ltd. provides high-quality Grade 6 titanium bars that meet international standards for aerospace, marine, and chemical processing industries. Our products are manufactured under strict quality control and offered in various dimensions and custom specifications to meet the specific needs of different engineering projects.

Features of Grade 6 Titanium Bar

Balanced mechanical strength and ductility

Excellent corrosion resistance in marine and chemical environments

Good weldability and formability

Resistant to fatigue and stress cracking

Performs well under elevated temperatures

Biocompatible and environmentally friendly

Specifications of Grade 6 Titanium Bar

| Parameter | Value |

|---|---|

| Grade | Grade 6 (Ti-5Al-2.5Sn) |

| Alloy Type | Alpha-Beta Alloy |

| Standard | ASTM B348, AMS 4911, ISO 5832 |

| Tensile Strength | ≥ 760 MPa |

| Yield Strength | ≥ 690 MPa |

| Elongation | ≥ 13 Percent |

| Density | 4.48 g/cm³ |

| Melting Point | 1660 °C |

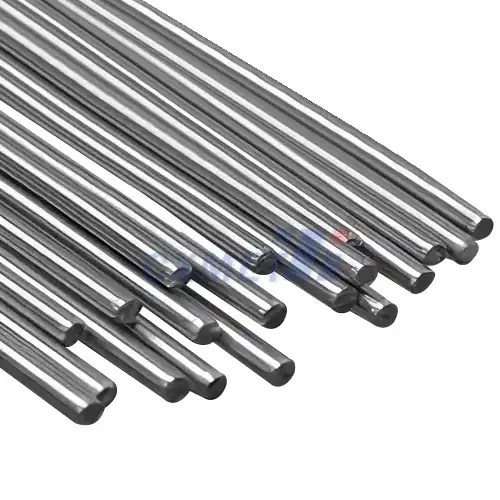

| Bar Diameter Range | 4 mm to 300 mm |

| Length | Up to 6000 mm (customized available) |

| Surface Finish | Polished, Ground, Turned, Pickled |

| Tolerance | H9, H10, or as per drawing |

|

|

|

Applications of Grade 6 Titanium Bar

Grade 6 Titanium Bar is widely used across demanding industries where both strength and corrosion resistance are crucial. Key applications include:

Aerospace components such as frames, fasteners, and structural parts

Marine engineering including offshore equipment and submarine structures

Chemical processing plants involving acidic or chloride-rich environments

High-performance automotive and motorsport parts

Heat exchangers and condensers in power plants

|

|

|

|

|

|

Working Environment for Grade 6 Titanium Bar

Grade 6 titanium performs exceptionally in both oxidizing and mildly reducing environments. It offers stable mechanical properties at elevated temperatures up to 400°C and exhibits high resistance to seawater, acids, and alkalis. This makes it suitable for:

Seawater and brine exposure

Sulfuric and nitric acid conditions

Chlorine-rich chemical media

High-vibration and cyclic loading environments

Cleanroom and vacuum applications

Customization Available

At Shaanxi CXMET Technology Co., Ltd., we understand that each project may require unique specifications. Therefore, we offer complete customization for our Grade 6 Titanium Bars including:

Custom diameters and lengths

Special tolerances and surface finishes

Tailored mechanical property requirements

Heat treatment and machining services

Third-party inspections and certifications

We welcome OEM and special engineering project requirements. Our technical team will work closely with you to ensure the product fully meets your expectations.

Key Advantages of Grade 6 Titanium Bar

Superior strength-to-weight ratio compared to stainless steel

Extended service life due to outstanding corrosion resistance

Cost-efficient in the long term with lower maintenance needs

Environmentally friendly and fully recyclable

Excellent resistance to fatigue and stress conditions

Ideal substitute for heavier metal components in design optimization

Compliant with international aerospace and industrial standards

Packaging and Logistics

All titanium bars are packed securely to prevent mechanical damage during transportation. Our standard packaging includes:

Plastic wrapping and foam layers for protection

Wooden crates or pallets with fumigation certificates

Customized labeling for traceability

Export-worthy packaging compliant with international shipping norms

We support fast delivery by sea, air, or express logistics, with full documentation provided including material test reports and certificates of origin.

|

|

|

|

Company Overview

Shaanxi CXMET Technology Co., Ltd., founded in 2005, is headquartered in China's Titanium Valley and operates a 50,000 m² facility. With 10 million RMB in registered capital and over 80 technical staff, we specialize in R&D, manufacturing, and exporting of non-ferrous and refractory metals, including titanium, nickel, tantalum, niobium, zirconium, molybdenum, and tungsten.

Our materials serve industries ranging from marine and oil & gas to medical, chemical, electronics, and aerospace. We uphold integrity, development, innovation, and excellence in service. Our mission is to create value for clients, benefit our enterprise, and support employee growth. With a forward-looking vision, we strive to innovate and lead the global titanium market.

Factory show

|

|

|

|

Production workshop

|

|

|

|

|

|

Production Equipments

Main Products

Why Choose Us – Shaanxi CXMET Technology Co., Ltd.

Shaanxi CXMET Technology Co., Ltd. is your trusted partner in advanced titanium materials. Founded in 2005 with a registered capital of 10 million RMB, we operate from a 50000 square meter facility in the heart of China’s Titanium Valley. With more than 20 years of industrial expertise, we are proud to serve global clients with the following advantages:

Extensive Product Range: We supply titanium, nickel, tantalum, niobium, molybdenum, zirconium, and their alloys.

Outstanding Production Capabilities: We operate advanced CNC, forging, and heat-treatment equipment.

Continuous Innovation: We actively invest in R&D to develop new titanium materials and processing techniques.

Leading Technological Edge: Backed by over 80 skilled technicians, we are committed to precision manufacturing.

Customized Offerings: We offer flexible, tailor-made solutions to meet your specific needs.

Global Reach: Our products are widely used in aerospace, marine, chemical, energy, medical, and vacuum industries.

Our mission is to create value for customers, generate sustainable growth, and provide a platform for innovation. We are guided by integrity, excellence, and service — values that shape our daily operations and long-term vision.

FAQ

Q1: What standards do your Grade 6 titanium bars comply with

A1: Our bars conform to ASTM B348, AMS 4911, ISO standards, and other international specifications.

Q2: Can you provide third-party testing reports

A2: Yes, we work with SGS, TUV, or customer-designated labs to provide full inspection documentation.

Q3: What is the minimum order quantity

A3: We offer flexible MOQ policies. Please contact us with your specific quantity and size requirements.

Q4: Do you offer machining or surface treatments

A4: Yes, we provide turning, grinding, polishing, pickling, and custom machining services.

Q5: What payment methods do you accept

A5: T/T, L/C, Western Union, and PayPal are available for international transactions.

Q6: How fast can you deliver after order confirmation

A6: Typically 7-15 working days for stock items, and 15-30 days for custom orders.

Contact Us

We are ready to support your titanium needs with high precision, quality assurance, and international logistics. Contact our sales team today for a personalized quote, free technical consultation, or to discuss your upcoming project.

Email: sales@cxmet.com

Tel & WhatsApp: +86 158 9119 2169

Let Shaanxi CXMET Technology Co., Ltd. be your reliable supplier of high-performance Grade 6 Titanium Bars for demanding industrial environments.

hotTags:Grade 6 Titanium Bar,supplier,wholesale,China,factory,manufacturer,OEM,Customized,trader,for sale,in stock,free sample,for sale.

YOU MAY LIKE

Gr9 Titanium Bar

Brand: CXMET

Place Of Origin: China

Grade: Titanium GR-9

Standard: ASTM B348 / ASME SB348, AMS 4976, AMS 4956

Type: Seamless / Welded / Fabricated / LSAW Pipes

Form : Round, Square, Hex (A/F), Rectangle, Billet, Ingot, Forging Etc.

6Al4V AMS 4928 Titanium Bar

Brand: CXMET

Place Of Origin: China

Diameter 2

Max Length 144

Grade: Grade 5

Full Length true

Material: Titanium

Shape: Bar-Round

Custom: Cut Warehouse 1

Alloy: 6AL-4V Grade 5

Ti-13Nb-13Zr Titanium Rod

Brand: CXMET

Place Of Origin: China

Type: Titanium Bars

Application: Industrial

Technique: Cold Rolled

Grade: Gr1 Gr2

Shape: Round

Density: 4.5g/cm3

Titanium Welding Rod

Brand: CXMET

Place Of Origin: China

Grade: Gr1 Gr2 Gr7 Gr5

Ti (Min): 99.6%

Strength: 345MPa

Surface: Pickling Polished

Shape: Spool Coil Straight

Standard: ASTM B863

Certification: ISO9001:2015

Strength: 435MPa

Application: Industrial

Gr23 Ti 6AL4V Eli Medical Titanium Bar

Brand: CXMET

Place Of Origin: China

Grade: Gr23 Ti6AL4V Eli

Standard: ASTM F136

Specification: Dia4~100mm*(1000~3000)mm

Technique: Cold Rolling/Hot Rolling

Surface: Pickling/Polished

Application: industrial

High Standard Gr12 Titanium Alloy Bar

Brand: CXMET

Place Of Origin: China

Gr12 Titanium Alloy Bar/Titanium Sheet/Titanium Tube

Product specification range: Diameter 6-500mm, Length 0.5-30m

Product Specification Range: Thickness 0.5-80mm, length 1-12m, width 0.5-3m

Product Specification Range: OD 6-530mm, wall thickness 0.5-50mm

Length 1-12m

Shape: Round

tianium Alloy 6Al-2Sn-4Zr-6Mo Round Bar

Brand: CXMET

Place Of Origin: China

Type: Titanium Bars

Application: Industrial, Medical

Technique: Hot Rolled

Shape: Round

Classification: Commercially Pure

High Quality Gr1 Pure Titanium Bar

Brand: CXMET

Place Of Origin: China

Type: Titanium Bars

Application: Industrial

Technique: Cold Rolled

Grade: GR1

Shape: Round

Transport Package: As Your Requirements