- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

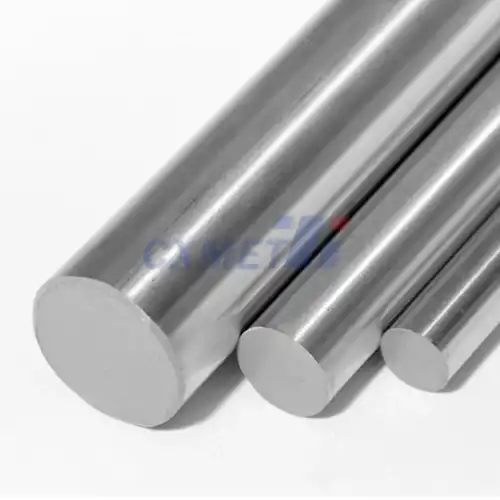

6Al4V AMS 4928 Titanium Bar

Max Length 144

Grade: Grade 5

Full Length true

Material: Titanium

Shape: Bar-Round

Custom: Cut Warehouse 1

Alloy: 6AL-4V Grade 5

6Al4V AMS 4928 Titanium Bar Product Introduction

Shaanxi CXMET Technology Co., Ltd. proudly offers the premium-grade 6Al4V AMS 4928 Titanium Bar, engineered to meet the most stringent aerospace and industrial specifications. As a top-tier α+ β titanium alloy, 6Al4V is known for its exceptional strength-to-weight ratio, excellent corrosion resistance, and superb mechanical performance at both ambient and elevated temperatures.

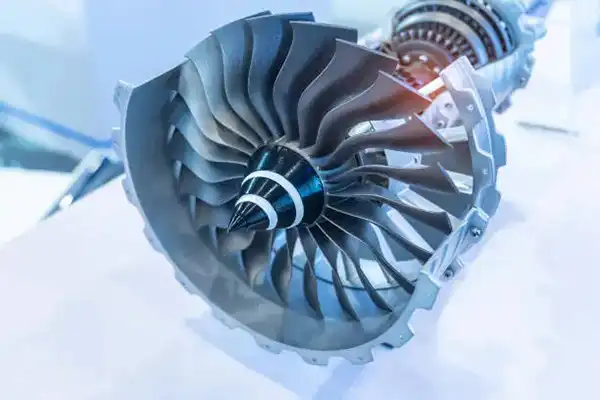

AMS 4928 is a specification under the Aerospace Material Specification standards, specifically governing bars, forgings, and forging stock made of titanium alloy Ti-6Al-4V. This grade is widely used in high-performance structural applications such as aircraft components, high-performance motorsport systems, and marine hardware, due to its reliable mechanical consistency and fatigue strength.

Our 6Al4V AMS 4928 titanium bars are manufactured using advanced production lines and strict quality control systems, ensuring outstanding consistency and compliance with international standards.

Features of 6Al4V AMS 4928 Titanium Bar

-

High tensile and yield strength (up to 895 MPa and 828 MPa respectively)

-

Excellent fatigue and crack resistance

-

Superior resistance to corrosion in marine and chemical environments

-

Low density (4.43 g/cm³), enabling significant weight reduction in structural parts

-

Excellent weldability and formability

-

Stable mechanical performance at elevated temperatures up to 400°C

-

Biocompatible, suitable for medical-grade applications

Specifications of 6Al4V AMS 4928 Titanium Bar

| Standard | AMS 4928 / ASTM B348 / ISO 5832-3 |

|---|---|

| Grade | Ti-6Al-4V (Grade 5) |

| Diameter Range | 6 mm – 300 mm (custom sizes available) |

| Length | Up to 6000 mm or as per customer requirement |

| Surface Finish | Peeled, Polished, Ground, Turned |

| Density | 4.43 g/cm³ |

| Tensile Strength | ≥895 MPa |

| Yield Strength | ≥828 MPa |

| Elongation | ≥10% |

| Microstructure | Fully α+β annealed |

|

|

Applications of 6Al4V AMS 4928 Titanium Bar

-

Aerospace: Landing gear components, aircraft structural frames, fasteners, turbine engine parts

-

Motorsports: Lightweight engine parts, suspension components, high-performance bolts

-

Marine Engineering: Submarine parts, ship shafts, offshore platform connectors

-

Medical Devices: Surgical instruments, dental tools, prosthetics (non-implant grade)

-

Chemical Industry: Corrosive environment tools, reactors, piping systems

-

Energy: Turbine blades, high-temperature fasteners in power generation equipment

|

|

|

|

|

|

Working Environment of 6Al4V AMS 4928 Titanium Bar

6Al4V titanium bars are suitable for use in:

-

High-stress mechanical environments

-

Saltwater and marine atmospheres

-

Chemical processing plants

-

Aerospace altitude and variable pressure conditions

-

High-temperature ranges (up to 400°C continuously)

-

Areas with exposure to oxidizing and reducing agents

Custom Fabrication Available

At Shaanxi CXMET Technology Co., Ltd., we understand that every customer has unique project demands. We provide:

-

Custom dimensions (diameter, length, tolerance)

-

Tailored mechanical properties (through heat treatment)

-

Specific surface finishing (grinding, polishing, turning)

-

Rapid prototyping and small-batch production

-

Precision cutting and machining based on drawings

OEM and ODM orders are welcome. Our engineering team works closely with international clients to deliver bespoke titanium solutions.

Key Advantages of 6Al4V AMS 4928 Titanium Bar

-

High Strength-to-Weight Ratio: Ideal for aerospace and automotive weight-saving designs

-

Long Service Life: Excellent fatigue strength ensures durability

-

Corrosion Resistance: Withstands acidic, chloride, and marine exposures better than steel

-

Thermal Stability: Maintains performance under elevated temperatures

-

Easy Fabrication: Good machinability and weldability make it suitable for complex assemblies

-

Versatility: Used across industries from aviation to biomedical

-

Biocompatibility: Non-toxic and safe for limited medical applications

Packaging and Logistics

We ensure all 6Al4V AMS 4928 titanium bars are:

-

Packed in strong, seaworthy wooden cases or cartons

-

Protected with plastic film and foam to avoid surface damage

-

Labeled clearly with material grade, batch number, and dimensions

-

Shipped via air, sea, or express, based on customer requirements

-

Documented with Mill Test Certificate, Certificate of Origin, and other export documents

|

|

|

|

Company Overview

Shaanxi CXMET Technology Co., Ltd., founded in 2005, is headquartered in China's Titanium Valley and operates a 50,000 m² facility. With 10 million RMB in registered capital and over 80 technical staff, we specialize in R&D, manufacturing, and exporting of non-ferrous and refractory metals, including titanium, nickel, tantalum, niobium, zirconium, molybdenum, and tungsten.

Our materials serve industries ranging from marine and oil & gas to medical, chemical, electronics, and aerospace. We uphold integrity, development, innovation, and excellence in service. Our mission is to create value for clients, benefit our enterprise, and support employee growth. With a forward-looking vision, we strive to innovate and lead the global titanium market.

Factory show

|

|

|

|

Production workshop

|

|

|

|

|

|

Production Equipments

Main Products

Why Choose Us: Shaanxi CXMET Technology Co., Ltd.

-

Extensive Product Range: Titanium, nickel, zirconium, niobium, tantalum, molybdenum, and their alloys

-

Outstanding Production Capabilities: Advanced equipment for melting, forging, rolling, machining, and testing

-

Continuous Innovation: Committed to new alloy and application development

-

Global Export Experience: Deep knowledge of international requirements and logistics

-

Expert Technical Team: Over 80 professionals, including engineers and quality inspectors

-

Strategic Location: Based in "China Titanium Valley" with access to top suppliers and resources

Since 2005, Shaanxi CXMET Technology Co., Ltd. has grown into a global supplier of high-quality titanium products. We are guided by a core philosophy of integrity, innovation, development, and excellence in service. Our mission is to create value for customers, drive industrial progress, and provide growth opportunities for employees.

FAQ

Q1: What is the minimum order quantity (MOQ)?

A1: We can accept small quantity orders for samples or trials. Please contact us for details.

Q2: Can I get a free sample of the 6Al4V AMS 4928 Titanium Bar?

A2: Yes, sample pieces are available upon request. Freight cost is typically borne by the buyer.

Q3: What is the delivery time?

A3: Generally 7-15 working days depending on quantity and stock availability.

Q4: Do you offer machining or precision cutting services?

A4: Yes, we provide cutting, CNC machining, grinding, and polishing services as per drawing.

Q5: Are your titanium bars certified?

A5: All products come with complete mill test reports and certificates (EN10204 3.1 / 3.2, ISO, AMS, ASTM standards).

Contact Us

For the latest pricing, custom specifications, or expert advice on titanium bar applications, please get in touch with us today:

Email: sales@cxmet.com

Tel & WhatsApp: +86 15891192169

Let Shaanxi CXMET Technology Co., Ltd. be your trusted titanium alloy supplier for reliable, high-performance, and cost-effective titanium bar solutions worldwide.

hotTags:6Al4V AMS 4928 Titanium Bar,supplier,wholesale,China,factory,manufacturer,OEM,Customized,trader,for sale,in stock,free sample,for sale.

YOU MAY LIKE

titanium 6Al-4V Grade 5 Round Bar

Brand: CXMET

Place Of Origin: China

Type: Titanium Bars

Application: Medical

Technique: Hot Rolled

Grade: GR5

Shape: Round

Outer Diameter: 6-200mm

Grade 6 Titanium Bar

Product Name: Grade 6 titanium

Brand: CXMET

Place Of Origin: China

Material: Titanium

Surface: Polished/Pickling

Type: Round

Shape: Round bar

Standard: ASTM B348, ASTM F136, AMS 4920

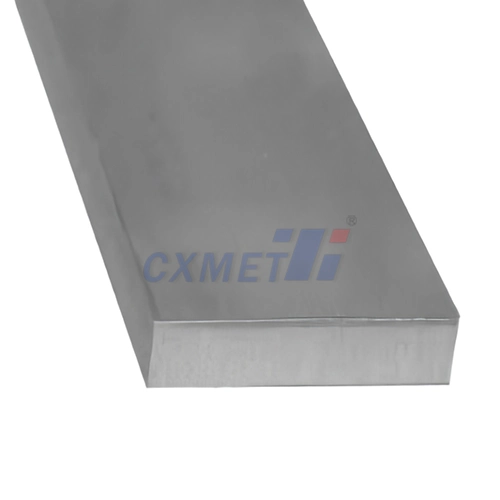

Titanium Rectangular Bar

Brand: CXMET

Place Of Origin: China

Thickness:4.5

Width: 4.75

Max Length:144

Alloy: 6AL-4V Grade 5

MTR Availability: Yes

Material: Titanium

Shape: Bar-Rectangle

Nitinol Bar Stock

Brand: CXMET

Place Of Origin: China

Specification: ASTM F2063

Af Temperature -10°C to 120°C

Size >0.2” Diameter

Surface: Black, Pickled, Polished

Other types: Bar, rectangular bar and other customized shape

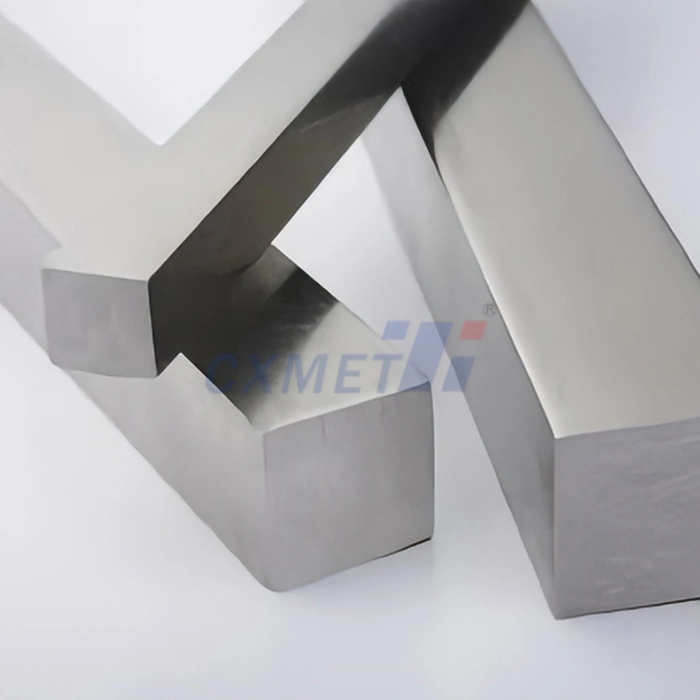

Gr12 Titanium Square Bar

Brand: CXMET

Place Of Origin: China Shape:Square

Grade: Gr12

Standard: ASTM B348

Technique: Rolling

Certificates: ISO 9001:2015

Gr5 Titanium Bar

Brand: CXMET

Place Of Origin: China

Type: Titanium Bars

Application: Industrial

Technique: Hot Rolled

Shape: Round

Length: 50-6000mm

Titanium Square Bar

Brand: CXMET

Place Of Origin: China

Material: GR1,GR2,GR3,GR4,GR5,6AL4VEli,GR7,GR9,GR12,GR23

Standards: ASTM B348,ASTM F67,ASTM F136

Surface : Polished bright,machined ,grind

Supply condition: Hot rolling ,cold drawing ,annealed

Shape: Square

Gr23 Ti 6AL4V Eli Medical Titanium Bar

Brand: CXMET

Place Of Origin: China

Grade: Gr23 Ti6AL4V Eli

Standard: ASTM F136

Specification: Dia4~100mm*(1000~3000)mm

Technique: Cold Rolling/Hot Rolling

Surface: Pickling/Polished

Application: industrial