- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

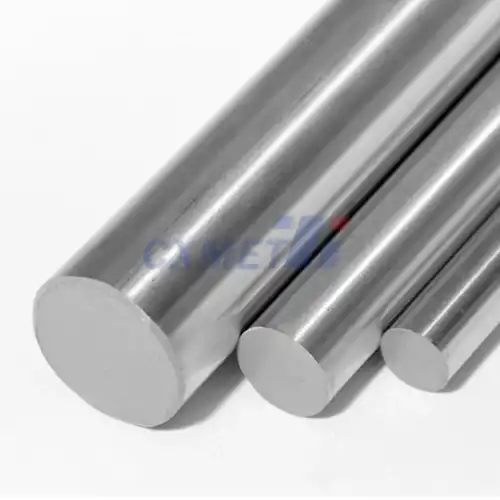

Titanium Hex Bar For Sale

Place Of Origin: China

Material: Pure titanium titanium alloy

Grade: Gr1,Gr2,Gr5,Gr7,Gr12,etc

Color: Ti Natural

Applacation: Industry Diameter:60-50mm

Length <6000mm(nomal size)

Product Introduction – Titanium Hex Bar For Sale

Shaanxi CXMET Technology Co., Ltd. proudly presents our premium-grade Titanium Hex Bar, manufactured with advanced techniques and strict quality control standards. As a vital component in numerous demanding industries, titanium hex bars are widely recognized for their high strength-to-weight ratio, excellent corrosion resistance, and biocompatibility. Our titanium hex bars are available in a wide range of grades (Gr1–Gr23) and dimensions, meeting ASTM B348, AMS 4928, and other international standards.

Titanium Hex Bars are machined with a six-sided cross-section, making them ideal for applications requiring strong mechanical grip and torque transfer. This unique geometry, combined with the excellent properties of titanium, makes our hex bars highly preferred for aerospace fasteners, medical components, marine fittings, and chemical processing parts.

Whether you’re looking for small batch prototyping materials or large-scale industrial supply, Shaanxi CXMET is your reliable titanium partner.

Key Features of Titanium Hex Bar For Sale

Excellent Corrosion Resistance: Resists acids, chlorides, and seawater environments.

High Strength-to-Weight Ratio: Comparable strength to steel at nearly half the weight.

Biocompatibility: Non-toxic and ideal for medical and dental implants.

Non-Magnetic and Low Thermal Expansion: Perfect for precision engineering and electronic applications.

Exceptional Fatigue Resistance: Endures cyclic stress in aerospace and automotive sectors.

Temperature Stability: Maintains strength and stability at elevated temperatures.

Precision Machined: Tight tolerance control and smooth finish.

Specifications of Titanium Hex Bar For Sale

| Grade | Type | Composition | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) | Features |

|---|---|---|---|---|---|---|

| Gr1 | CP Ti | ≥99.5% Ti | 240 | 170 | 24 | Very soft, high corrosion resistance |

| Gr2 | CP Ti | ≥99.2% Ti | 345 | 275 | 20 | Balance of strength and corrosion resistance |

| Gr5 | α+β | Ti-6Al-4V | 895 | 828 | 10 | Aerospace grade, high heat resistance |

| Gr7 | CP+Pd | Ti + 0.2% Pd | 340 | 275 | 20 | Resistant to strong acids |

| Gr9 | α | Ti-3Al-2.5V | 620 | 483 | 15 | Good formability and welding |

| Gr12 | α | Ti-0.3Mo-0.8Ni | 480 | 345 | 18 | Strength and corrosion resistance in harsh environments |

| Gr23 | α+β (ELI) | Ti-6Al-4V ELI | 860 | 795 | 14 | Medical grade, ultra low interstitials |

Other grades (Gr3, Gr4, Gr19–22) available upon request.

|

|

|

Applications of Titanium Hex Bar For Sale

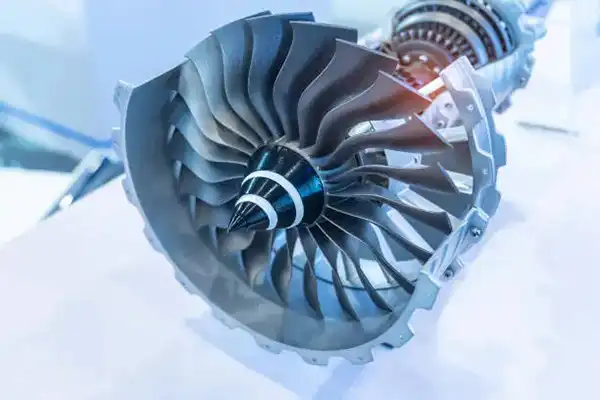

Aerospace: Fasteners, landing gear, brackets, and structural frames.

Chemical Processing: Pumps, valves, and reactors.

Medical Industry: Bone screws, dental implants, surgical tools.

Marine Engineering: Ship fittings, desalination components.

Automotive Racing: Performance bolts and chassis parts.

Oil and Gas: Downhole equipment, pressure vessels.

|

|

|

|

|

|

Operating Environments of Titanium Hex Bar

Titanium Hex Bars from CXMET excel in:

Highly acidic and chloride-rich environments

Saltwater and marine atmospheres

Cleanroom and vacuum applications

High-temperature exposure (especially Gr5, Gr22)

High-vibration and fatigue-prone systems

Customization Options

At Shaanxi CXMET, we offer complete customization:

Sizes: From 6mm to 100mm across flats

Lengths: Cut-to-length bars from 100mm to 6000mm

Grades: CP Titanium (Gr1–4), Titanium Alloys (Gr5, Gr9, Gr12, Gr23, etc.)

Surface Finish: Pickled, polished, turned, or centerless ground

Tolerance: As per ISO, ASTM, or custom requirements

Major Advantages of Titanium Hex Bar For Sale

Lightweight yet strong – reduces part weight without compromising performance

Long-term durability – corrosion-resistant for extended service life

Excellent value – minimal maintenance and longer replacement cycles

Environmentally safe – no heavy metal leaching, fully recyclable

Global availability – fast international shipping from China’s Titanium Valley

Packaging and Logistics

We ensure that every Titanium Hex Bar is securely packed to prevent damage:

Packaging: PE film, kraft paper, bubble wrap, wooden boxes or crates

Marking: Grade, heat number, dimension, batch ID

Shipping: DHL, FedEx, air freight, sea freight options available

Lead Time: Standard delivery within 7–15 days; urgent supply possible

|

|

|

|

Company Overview

Shaanxi CXMET Technology Co., Ltd., founded in 2005, is headquartered in China's Titanium Valley and operates a 50,000 m² facility. With 10 million RMB in registered capital and over 80 technical staff, we specialize in R&D, manufacturing, and exporting of non-ferrous and refractory metals, including titanium, nickel, tantalum, niobium, zirconium, molybdenum, and tungsten.

Our materials serve industries ranging from marine and oil & gas to medical, chemical, electronics, and aerospace. We uphold integrity, development, innovation, and excellence in service. Our mission is to create value for clients, benefit our enterprise, and support employee growth. With a forward-looking vision, we strive to innovate and lead the global titanium market.

Factory show

|

|

|

|

Production workshop

|

|

|

|

|

|

Production Equipments

Main Products

Why Choose Us – Shaanxi CXMET Technology Co., Ltd.

Extensive Product Range: Covering titanium, nickel, tantalum, niobium, molybdenum, tungsten, zirconium.

Advanced Production Facilities: 50,000㎡ factory area with CNC, forging, rolling, machining, and inspection equipment.

Continuous Innovation: Dedicated to R&D and new material solutions.

Customization Experts: OEM/ODM services tailored to client needs.

Global Market Focus: 80+ engineers, strong international logistics network.

Excellent Reputation: Trusted by aerospace, medical, marine, and energy sectors.

Corporate Values: Integrity, development, innovation, service excellence.

FAQ – Titanium Hex Bar

Q1: What is the minimum order quantity?

A: We accept both small and large batch orders, with flexible MOQs.

Q2: Can you provide material test certificates?

A: Yes, we offer full MTCs with mechanical, chemical, and dimensional reports.

Q3: Do you supply hex bars in custom shapes?

A: Yes, special profiles and shapes can be manufactured upon request.

Q4: What grades are suitable for marine or saltwater use?

A: Gr2, Gr7, and Gr20 are excellent for marine applications.

Q5: Is your product export compliant?

A: All our materials comply with international export regulations and standards.

Contact Us – Get Your Quote Today

For the latest price, specifications, or custom solutions, contact us today!

Email: sales@cxmet.com

Tel & WhatsApp: +86 15891192169

hotTags:Titanium Hex Bar For Sale,supplier,wholesale,China,factory,manufacturer,OEM,Customized,trader,for sale,in stock,free sample,for sale.

YOU MAY LIKE

Grade 6 Titanium Bar

Product Name: Grade 6 titanium

Brand: CXMET

Place Of Origin: China

Material: Titanium

Surface: Polished/Pickling

Type: Round

Shape: Round bar

Standard: ASTM B348, ASTM F136, AMS 4920

Nitinol Bar Stock

Brand: CXMET

Place Of Origin: China

Specification: ASTM F2063

Af Temperature -10°C to 120°C

Size >0.2” Diameter

Surface: Black, Pickled, Polished

Other types: Bar, rectangular bar and other customized shape

Ti13Nb13Zr Rod

Brand: CXMET

Place Of Origin: China

Classification:Round/Square/Hexagon

Standard:ASTM B348,ASTM F67,ASTM F136,ASME SB348

Grade: Gr1-Gr7,Gr5,Gr5 Eli,Gr12

Size: Dia(0.8mm-100mm)*Length(≤3000mm)

Processing Method:Forging/Extrusion/Rolling/Cold drawing

Dia 10mm Titanium Rod In Medical

Brand: CXMET

Place Of Origin: China

Shape: Round

Grade: Gr5

Weight: According the dimension

Processing Service :Rolling, Ground

Material: titanium

Surface :Treatment Ground

MOQ: 10 KG

Standard :ASTM B348 ASTM F136

Package: Standard Wooden Case

Stock Size: Dia3-40mm Titanium Rod

Gr7 Titanium Rod

Brand: CXMET

Place Of Origin: China

Standrd: ASTM B348 ASTM F136 AMS4928 ASTMF1295

Specifaction φ>6mm Length(Max)6000mm

Surface :Bright

Technology: Forging/Rolling

Content of Pb: 0.12---0.25%

Application: Medical, Aviation, Petrochemical, Metallurgy, Electroplating

Vacuum: Coating, Sports and other Industries.

Gr23 Ti 6AL4V Eli Medical Titanium Bar

Brand: CXMET

Place Of Origin: China

Grade: Gr23 Ti6AL4V Eli

Standard: ASTM F136

Specification: Dia4~100mm*(1000~3000)mm

Technique: Cold Rolling/Hot Rolling

Surface: Pickling/Polished

Application: industrial

tianium Alloy 6Al-2Sn-4Zr-6Mo Round Bar

Brand: CXMET

Place Of Origin: China

Type: Titanium Bars

Application: Industrial, Medical

Technique: Hot Rolled

Shape: Round

Classification: Commercially Pure

Gr23 Medical Titanium Rod

Brand: CXMET

Place Of Origin: China

Type: Titanium Bars

Application: Industrial

Technique: Cold Rolled

Grade: Gr1 Gr2

Shape: Round

Density: 4.5g/cm3