- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Titanium Rectangular Bar

Place Of Origin: China

Thickness:4.5

Width: 4.75

Max Length:144

Alloy: 6AL-4V Grade 5

MTR Availability: Yes

Material: Titanium

Shape: Bar-Rectangle

Product Introduction

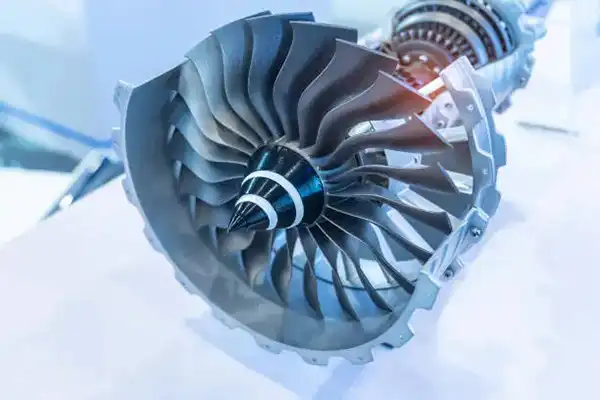

Shaanxi CXMET Technology Co., Ltd. proudly offers high-performance Titanium Rectangular Bars to meet the diverse needs of global industries. Engineered for strength, corrosion resistance, and weight efficiency, our titanium rectangular bars are produced from a wide range of titanium grades, including CP titanium (Gr1–Gr4) and titanium alloys (Gr5, Gr7, Gr9, Gr12, Gr23, etc.). These bars are ideal for demanding applications in aerospace, marine, medical, chemical, energy, and industrial manufacturing sectors.

With over 20 years of expertise and a registered capital of 10 million, Shaanxi CXMET is located in China's "Titanium Valley" and operates with cutting-edge manufacturing capabilities and a dedication to international standards. We are committed to innovation and customization to ensure optimal solutions for each customer.

Features of Titanium Rectangular Bar

High Strength-to-Weight Ratio: Lightweight yet remarkably strong, perfect for structural applications where reduced mass is crucial.

Excellent Corrosion Resistance: Performs reliably in aggressive environments such as seawater, acid, and chlorine-based systems.

Temperature Stability: Maintains mechanical integrity even under high-temperature conditions.

Biocompatibility: Suitable for medical use, including implants and surgical instruments (especially Gr1, Gr23).

Superior Machinability: Compatible with various cutting, forming, and welding processes.

Extended Service Life: Requires less maintenance and offers excellent fatigue resistance.

Specifications of Titanium Rectangular Bar

| Grade | Type | Alloy Composition | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) | Notable Feature |

|---|---|---|---|---|---|---|

| Gr1 | CP Ti | ≥99.5% Ti | 240 | 170 | 24 | Highest ductility, excellent corrosion resistance |

| Gr2 | CP Ti | ≥99.2% Ti | 345 | 275 | 20 | Well-balanced strength and corrosion resistance |

| Gr5 | α+β | Ti-6Al-4V | 895 | 828 | 10 | High strength, heat resistant |

| Gr7 | CP Ti | Ti + 0.2% Pd | 340 | 275 | 20 | Superior acid corrosion resistance |

| Gr9 | α | Ti-3Al-2.5V | 620 | 483 | 15 | Lightweight, good weldability |

| Gr23 | α+β ELI | Ti-6Al-4V ELI | 860 | 795 | 14 | Medical-grade purity and toughness |

Custom dimensions and tolerances are available upon request.

|

|

|

|

|

Product Attributes

- High strength-to-weight ratio

- Corrosion resistance

- Excellent thermal stability

- Biocompatibility

- Non-magnetic

- High melting point

Product Functions

Our titanium rods for sale serves as a structural component in aerospace, medical, marine, automotive, and architectural industries. It is widely used in manufacturing frames, supports, shafts, braces, and various structural elements requiring lightweight and robust materials.

Features

- Precision engineering

- Consistent mechanical properties

- Uniform surface finish

- Customizable dimensions

- Exceptional weldability

Advantages and Highlights

- Superior strength and durability

- Resistance to corrosion in harsh environments

- Lightweight design for enhanced efficiency

- Biocompatibility suitable for medical implants

- Versatility in application across industries

Application Areas

- Aerospace: aircraft frames, landing gears

- Medical: surgical implants, prosthetics

- Automotive: chassis components, exhaust systems

- Marine: boat hulls, propeller shafts

- Architecture: structural elements, facades

|

|

|

|

|

|

Working Environment

Titanium rectangular bars excel in environments involving:

Saltwater and marine exposure

Acidic and alkaline chemical solutions

High temperatures and thermal cycling

Biologically active surroundings (for implants and medical tools)

High vibration and fatigue-load conditions

Customization Options

Shaanxi CXMET provides full customization services:

Dimensions: Thickness, width, and length can be tailored

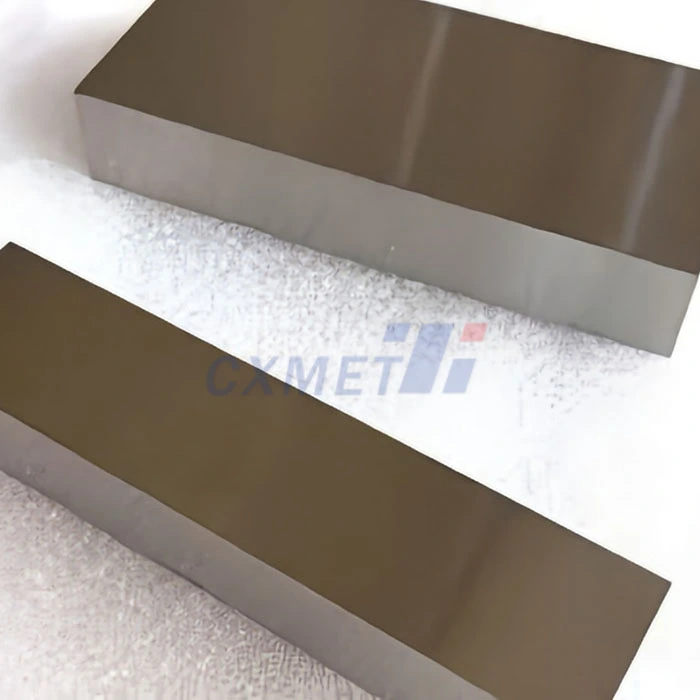

Surface finishes: Polished, pickled, sandblasted

Grades: CP and alloyed titanium grades available

Standards: ASTM B348, AMS 4928, ISO 5832-3, DIN 17851, etc.

Machining and fabrication services: CNC cutting, forging, welding

Key Advantages of Titanium Rectangular Bar

Lightweight with high tensile strength — ideal for weight-sensitive applications.

Exceptional corrosion resistance — especially in chloride, acidic, and marine environments.

Non-toxic and biocompatible — suitable for both external and internal medical applications.

Extended fatigue life — suitable for applications requiring repetitive stress endurance.

Cost-effective over time — due to lower maintenance and long operational life.

Packaging & Logistics

All titanium rectangular bars are:

Individually wrapped in corrosion-resistant packaging

Packed in strong wooden cases or crates with foam padding

Clearly labeled with grade, size, batch number, and heat number

Shipped via air, sea, or land with full export documentation

Global delivery within 7–15 business days for standard orders

|

|

|

|

Company Overview

Shaanxi CXMET Technology Co., Ltd., founded in 2005, is headquartered in China's Titanium Valley and operates a 50,000 m² facility. With 10 million RMB in registered capital and over 80 technical staff, we specialize in R&D, manufacturing, and exporting of non-ferrous and refractory metals, including titanium, nickel, tantalum, niobium, zirconium, molybdenum, and tungsten.

Our materials serve industries ranging from marine and oil & gas to medical, chemical, electronics, and aerospace. We uphold integrity, development, innovation, and excellence in service. Our mission is to create value for clients, benefit our enterprise, and support employee growth. With a forward-looking vision, we strive to innovate and lead the global titanium market.

Factory show

|

|

|

|

Production workshop

|

|

|

|

|

|

Production Equipments

Main Products

Why Choose Shaanxi CXMET Technology Co., Ltd.

Extensive Product Range: From titanium to zirconium, tantalum, and more.

Outstanding Production Capacity: 50,000 m² facility with advanced CNC and forging lines.

Innovation & R&D: Constantly developing new alloys and product designs.

Custom Solutions: OEM support and client-specific production strategies.

Experienced Team: 80+ professional technicians ensure top-level manufacturing.

Trusted Supplier: Over 20 years of industrial partnerships with positive global feedback.

Our strong corporate culture rooted in integrity, innovation, development, and service excellence guides us in everything we do.

FAQ

Q1: What grades of titanium rectangular bars do you supply?

A1: We offer Gr1 to Gr23, including both CP titanium and titanium alloys.

Q2: Can you provide mill test certificates and third-party inspection reports?

A2: Yes, MTC and third-party inspection (SGS, BV, etc.) are available.

Q3: What are your minimum order quantities?

A3: MOQ depends on grade and size. For common grades, small quantities are accepted.

Q4: Do you offer machining or further fabrication?

A4: Yes, we offer CNC machining, drilling, surface treatment, and custom shapes.

Q5: How long is the lead time?

A5: Generally 7–15 days depending on stock and customization requirements.

Contact Us

We welcome inquiries from all over the world. Whether you are a distributor, engineering firm, or OEM manufacturer, Shaanxi CXMET is your trusted partner for premium titanium rectangular bars.

Email: sales@cxmet.com

Tel & WhatsApp: +86 15891192169

hotTags:Titanium Rectangular Bar,supplier,wholesale,China,factory,manufacturer,OEM,Customized,trader,for sale,in stock,free sample,for sale.

YOU MAY LIKE

Grade 6 Titanium Bar

Product Name: Grade 6 titanium

Brand: CXMET

Place Of Origin: China

Material: Titanium

Surface: Polished/Pickling

Type: Round

Shape: Round bar

Standard: ASTM B348, ASTM F136, AMS 4920

Ti13Nb13Zr Rod

Brand: CXMET

Place Of Origin: China

Classification:Round/Square/Hexagon

Standard:ASTM B348,ASTM F67,ASTM F136,ASME SB348

Grade: Gr1-Gr7,Gr5,Gr5 Eli,Gr12

Size: Dia(0.8mm-100mm)*Length(≤3000mm)

Processing Method:Forging/Extrusion/Rolling/Cold drawing

Titanium 6Al7Nb Medical Bar

Brand: CXMET

Place Of Origin: China

Type: Titanium Rod

Application: Industrial

Technique: Cold Rolled

Grade: GR1

Shape: Round

Density: 4.5g/cm3

Ti-13Nb-13Zr Titanium Rod

Brand: CXMET

Place Of Origin: China

Type: Titanium Bars

Application: Industrial

Technique: Cold Rolled

Grade: Gr1 Gr2

Shape: Round

Density: 4.5g/cm3

Gr7 Titanium Rod

Brand: CXMET

Place Of Origin: China

Standrd: ASTM B348 ASTM F136 AMS4928 ASTMF1295

Specifaction φ>6mm Length(Max)6000mm

Surface :Bright

Technology: Forging/Rolling

Content of Pb: 0.12---0.25%

Application: Medical, Aviation, Petrochemical, Metallurgy, Electroplating

Vacuum: Coating, Sports and other Industries.

Gr23 Ti 6AL4V Eli Medical Titanium Bar

Brand: CXMET

Place Of Origin: China

Grade: Gr23 Ti6AL4V Eli

Standard: ASTM F136

Specification: Dia4~100mm*(1000~3000)mm

Technique: Cold Rolling/Hot Rolling

Surface: Pickling/Polished

Application: industrial

High Standard Gr12 Titanium Alloy Bar

Brand: CXMET

Place Of Origin: China

Gr12 Titanium Alloy Bar/Titanium Sheet/Titanium Tube

Product specification range: Diameter 6-500mm, Length 0.5-30m

Product Specification Range: Thickness 0.5-80mm, length 1-12m, width 0.5-3m

Product Specification Range: OD 6-530mm, wall thickness 0.5-50mm

Length 1-12m

Shape: Round

High Quality Gr1 Pure Titanium Bar

Brand: CXMET

Place Of Origin: China

Type: Titanium Bars

Application: Industrial

Technique: Cold Rolled

Grade: GR1

Shape: Round

Transport Package: As Your Requirements