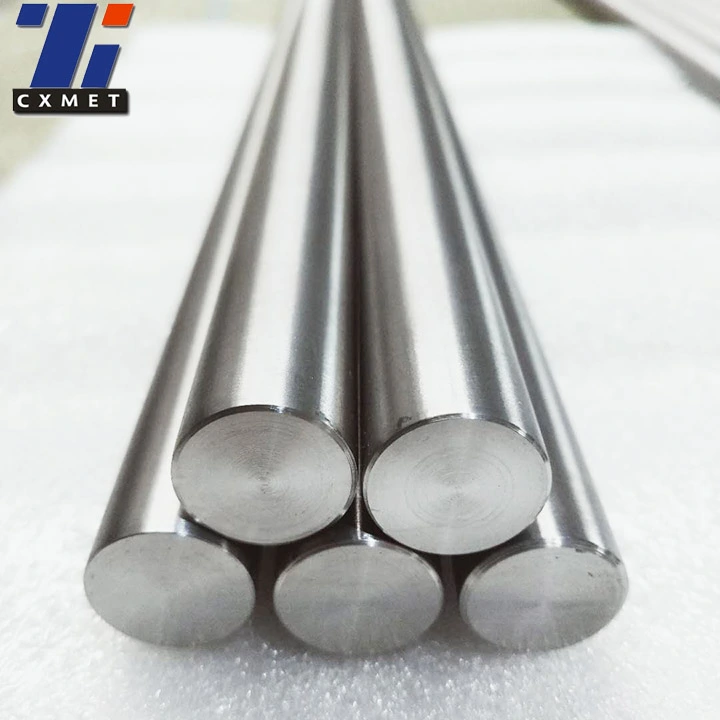

What are the key properties of Titanium Grade 4 Round Bar?

Titanium Grade 4 Round Bar, also known as commercially pure (CP) titanium grade 4, is characterized by its excellent combination of strength, ductility, and corrosion resistance. These properties make it an attractive option for various applications, including chemical processing equipment. Let's delve into the key properties that make Titanium Grade 4 Round Bar stand out:

- Corrosion Resistance: One of the most significant advantages of Titanium Grade 4 Round Bar is its exceptional corrosion resistance. It forms a stable, protective oxide layer on its surface when exposed to oxygen, providing excellent resistance to various corrosive environments. This makes it particularly suitable for use in chemical processing equipment that handles aggressive substances.

- Strength and Durability: Titanium Grade 4 offers higher strength compared to other commercially pure titanium grades. It has a minimum tensile strength of 550 MPa (80 ksi) and a yield strength of 483 MPa (70 ksi). This combination of strength and ductility allows it to withstand high pressures and mechanical stresses commonly encountered in chemical processing equipment.

- Low Density: With a density of approximately 4.51 g/cm³, Titanium Grade 4 is significantly lighter than many other metals used in chemical processing equipment, such as stainless steel. This low density translates to weight savings, which can be beneficial in certain applications where reducing overall equipment weight is important.

- Temperature Resistance: Titanium Grade 4 maintains its mechanical properties over a wide range of temperatures. It can be used in applications ranging from cryogenic temperatures up to about 600°C (1112°F), making it suitable for various chemical processing operations that involve temperature fluctuations.

- Biocompatibility: Although not directly related to chemical processing, it's worth noting that Titanium Grade 4 is biocompatible. This property makes it suitable for applications where contact with food or pharmaceuticals may occur during processing.

These properties collectively contribute to the suitability of Titanium Grade 4 Round Bar for use in chemical processing equipment. Its ability to resist corrosion, withstand mechanical stresses, and perform well in various temperature conditions makes it a versatile material choice for many chemical processing applications.

How does Titanium Grade 4 Round Bar compare to other materials for chemical processing equipment?

When considering materials for chemical processing equipment, it's essential to evaluate how Titanium Grade 4 Round Bar compares to other commonly used materials. This comparison helps in making informed decisions about material selection based on specific application requirements. Let's examine how Titanium Grade 4 stacks up against some popular alternatives:

- Titanium Grade 4 vs. Stainless Steel:

- Corrosion Resistance: Titanium Grade 4 generally offers superior corrosion resistance compared to most stainless steel grades, especially in highly aggressive environments.

- Strength-to-Weight Ratio: Titanium Grade 4 has a higher strength-to-weight ratio than stainless steel, making it advantageous in applications where weight reduction is crucial.

- Cost: Stainless steel is typically less expensive than Titanium Grade 4, which can be a significant factor in large-scale equipment manufacturing.

- Thermal Conductivity: Stainless steel has higher thermal conductivity, which may be preferable in heat exchange applications.

- Titanium Grade 4 vs. Hastelloy:

- Corrosion Resistance: Both materials offer excellent corrosion resistance, with Hastelloy potentially performing better in certain highly aggressive environments.

- Weight: Titanium Grade 4 is significantly lighter than Hastelloy, which can be advantageous in certain applications.

- Cost: Hastelloy is generally more expensive than Titanium Grade 4, making titanium a more cost-effective option in many cases.

- High-Temperature Performance: Hastelloy typically maintains its properties better at very high temperatures compared to Titanium Grade 4.

- Titanium Grade 4 vs. Other Titanium Grades:

- Strength: Grade 4 offers higher strength compared to lower grades like Grade 1 and 2, but lower than alloyed grades like Grade 5 (Ti-6Al-4V).

- Ductility: Grade 4 maintains good ductility while offering increased strength, striking a balance between formability and mechanical properties.

- Weldability: Grade 4 is generally easier to weld compared to higher-alloyed titanium grades, which can be beneficial in fabricating complex equipment.

When comparing Titanium Grade 4 Round Bar to other materials for chemical processing equipment, several factors should be considered:

- Chemical Compatibility: The specific chemicals involved in the process play a crucial role in material selection. Titanium Grade 4 excels in many corrosive environments, but certain chemicals may require alternative materials.

- Operating Conditions: Temperature, pressure, and mechanical stress levels in the equipment should be evaluated against the material properties of Titanium Grade 4 and alternatives.

- Life Cycle Cost: While the initial cost of Titanium Grade 4 may be higher than some alternatives, its long-term durability and potential for extended equipment life should be factored into the overall cost analysis.

- Fabrication Requirements: The ease of fabrication, including machining, welding, and forming, should be considered when choosing between Titanium Grade 4 and other materials.

- Regulatory Compliance: In some industries, such as food processing or pharmaceuticals, material selection may be influenced by regulatory requirements or industry standards.

By carefully evaluating these factors and comparing the properties of Titanium Grade 4 Round Bar with alternative materials, engineers and designers can make informed decisions about the most suitable material for specific chemical processing equipment applications.

|

|

|

What are the specific applications of Titanium Grade 4 Round Bar in chemical processing equipment?

Titanium Grade 4 Round Bar finds numerous applications in chemical processing equipment due to its unique combination of properties. Let's explore some specific applications where this material excels:

- Reactor Vessels and Tanks: Titanium Grade 4 is often used in the construction of reactor vessels and storage tanks for corrosive chemicals. Its excellent corrosion resistance makes it suitable for handling a wide range of aggressive substances, including chlorine compounds, organic acids, and oxidizing agents. The material's high strength-to-weight ratio also allows for the design of lighter yet durable vessels.

- Heat Exchangers: In chemical processing plants, heat exchangers are crucial components for controlling process temperatures. Titanium Grade 4 Round Bar is used to manufacture heat exchanger tubes and plates, particularly in applications involving corrosive fluids or seawater. Its resistance to pitting and crevice corrosion, combined with good thermal conductivity, makes it an excellent choice for these applications.

- Piping Systems: Chemical processing facilities often require complex piping systems to transport various substances. Titanium Grade 4 pipes and fittings are used in areas where corrosion resistance is paramount, such as in chlor-alkali plants or in systems handling chlorides, sulfuric acid, or other corrosive media.

- Valve Components: Valves play a critical role in controlling flow and pressure in chemical processing equipment. Titanium Grade 4 is used to manufacture valve stems, balls, and seats, especially in applications where corrosion resistance and durability are essential.

- Pump Components: In chemical processing, pumps are subjected to harsh conditions and corrosive fluids. Titanium Grade 4 is used to manufacture pump shafts, impellers, and casings, particularly in applications where traditional materials like stainless steel may not provide sufficient corrosion resistance.

- Distillation Columns: The construction of distillation columns and their internal components, such as trays and packing, may utilize Titanium Grade 4 in processes involving corrosive substances or where weight reduction is beneficial.

- Electrochemical Processing Equipment: In electrochemical processes, such as electroplating or electrolysis, Titanium Grade 4 is used for electrodes and other components due to its excellent corrosion resistance and electrical conductivity.

- Pressure Vessels: High-pressure applications in chemical processing may utilize Titanium Grade 4 for pressure vessel construction, especially when dealing with corrosive substances at elevated pressures.

- Flange and Fastener Components: In areas of chemical processing equipment where dissimilar metal contact occurs, Titanium Grade 4 fasteners and flange components can help prevent galvanic corrosion while maintaining structural integrity.

- Agitators and Mixing Equipment: The material's corrosion resistance and strength make it suitable for manufacturing agitator shafts, impellers, and other components in mixing equipment used in corrosive environments.

When considering Titanium Grade 4 Round Bar for these applications, it's important to note that proper design, fabrication, and maintenance practices are crucial to maximize the material's benefits. Some key considerations include:

- Welding Procedures: Titanium is highly reactive at elevated temperatures, requiring specialized welding techniques and inert gas shielding to prevent contamination and ensure strong, durable welds.

- Surface Treatment: While Titanium Grade 4 naturally forms a protective oxide layer, additional surface treatments like anodizing or passivation may be employed to enhance corrosion resistance further.

- Galvanic Corrosion Prevention: When used in conjunction with other metals, proper isolation techniques should be employed to prevent galvanic corrosion.

- Temperature Limitations: Although Titanium Grade 4 performs well in a wide temperature range, its use in very high-temperature applications (above 600°C) may require careful consideration or alternative materials.

- Cost Optimization: Given the higher cost of titanium compared to some alternative materials, it's often used selectively in areas where its properties provide the most significant benefits, rather than for entire equipment constructions.

In conclusion, Titanium Grade 4 Round Bar offers a compelling combination of properties that make it suitable for various applications in chemical processing equipment. Its corrosion resistance, strength, and durability contribute to increased equipment lifespan and reduced maintenance requirements in many corrosive environments. However, material selection should always be based on a thorough analysis of the specific application requirements, including chemical compatibility, operating conditions, and economic considerations. By carefully evaluating these factors, engineers and designers can determine whether Titanium Grade 4 Round Bar is the optimal choice for their chemical processing equipment needs.

At SHAANXI CXMET TECHNOLOGY CO., LTD, we take pride in our extensive product range, which caters to diverse customer needs. Our company is equipped with outstanding production and processing capabilities, ensuring the high quality and precision of our products. We are committed to innovation and continuously strive to develop new products, keeping us at the forefront of our industry. With leading technological development capabilities, we are able to adapt and evolve in a rapidly changing market. Furthermore, we offer customized solutions to meet the specific requirements of our clients. If you are interested in our products or wish to learn more about the intricate details of our offerings, please do not hesitate to contact us at sales@cxmet.com. Our team is always ready to assist you.

|

|

|

References

1. ASTM International. (2021). ASTM B348 - Standard Specification for Titanium and Titanium Alloy Bars and Billets.

2. Leyens, C., & Peters, M. (Eds.). (2003). Titanium and titanium alloys: fundamentals and applications. John Wiley & Sons.

3. Schutz, R. W., & Thomas, D. E. (1987). Corrosion of titanium and titanium alloys. ASM Handbook, 13, 669-706.

4. Boyer, R., Welsch, G., & Collings, E. W. (Eds.). (1994). Materials properties handbook: titanium alloys. ASM international.

5. Donachie, M. J. (2000). Titanium: a technical guide. ASM international.

6. Peters, M., Kumpfert, J., Ward, C. H., & Leyens, C. (2003). Titanium alloys for aerospace applications. Advanced engineering materials, 5(6), 419-427.