- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

How Safe Is Dia 10mm Titanium Rod In Medical Implants?

2025-08-06 13:51:16

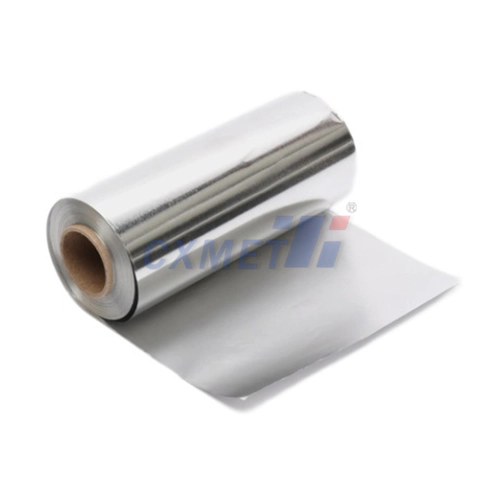

In the realm of medical implants, the safety and efficacy of materials used are of paramount importance. One such material that has gained significant attention in recent years is the Dia 10mm Titanium Rod in Medical. This specialized titanium rod, with its precise 10mm diameter, has become a cornerstone in various medical applications, particularly in orthopedic and dental implants. The question of its safety is not just a matter of academic interest but a crucial consideration for patients, surgeons, and medical device manufacturers alike. As we delve into this topic, we'll explore the unique properties of titanium that make it an ideal choice for medical implants, the specific benefits of the 10mm diameter rod, and the long-term effects on patient outcomes. Understanding the safety profile of the Dia 10mm Titanium Rod is essential for advancing medical treatments and ensuring the well-being of patients who rely on these implants for improved quality of life.

|

|

|

Biocompatibility: Titanium's Advantage in Implants

Chemical Inertness and Corrosion Resistance

The Dia 10mm Titanium Rod in Medical implants excels in biocompatibility due to its exceptional chemical inertness and corrosion resistance. When implanted in the human body, titanium forms a stable oxide layer on its surface, which acts as a protective barrier against corrosion. This oxide layer prevents the release of metal ions into the surrounding tissues, significantly reducing the risk of allergic reactions or rejection. The 10mm diameter of the rod provides an optimal surface area for this protective layer to form, enhancing its effectiveness. Furthermore, the corrosion resistance of titanium in bodily fluids is superior to many other metals, ensuring the longevity and stability of the implant over extended periods.

Low Allergenic Potential

One of the most significant advantages of the Dia 10mm Titanium Rod in Medical implants is its low allergenic potential. Titanium is known for its hypoallergenic properties, making it an ideal choice for patients with metal sensitivities. The 10mm diameter rod, in particular, provides a substantial surface area that minimizes the risk of localized reactions. This low allergenic potential is crucial in preventing complications such as inflammation, pain, or implant rejection. Studies have shown that titanium implants, including the 10mm rod, have a remarkably low incidence of allergic reactions compared to other metallic implants, contributing to their widespread use and patient safety.

Osseointegration Capabilities

The Dia 10mm Titanium Rod in Medical implants demonstrates excellent osseointegration capabilities, a critical factor in the success of orthopedic and dental implants. Osseointegration refers to the direct structural and functional connection between living bone tissue and the surface of the implant. The 10mm diameter of the rod provides an optimal surface for bone cells to adhere to and grow around, promoting strong integration with the surrounding bone. This integration is enhanced by the natural affinity of bone cells for titanium's oxide layer. The result is a stable, long-lasting connection between the implant and the bone, which is essential for the implant's functionality and the patient's comfort. The successful osseointegration of the 10mm titanium rod contributes significantly to its safety profile and clinical success.

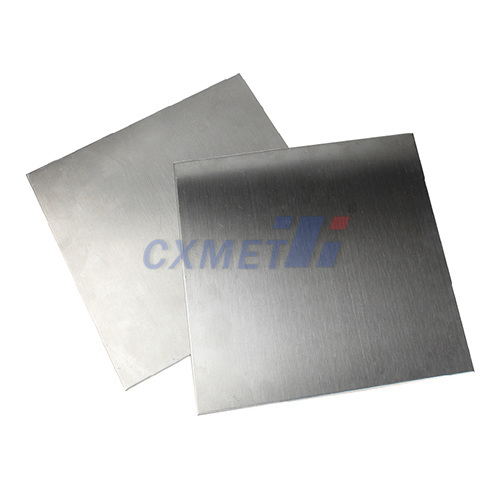

Strength vs. Size: 10mm Rod's Structural Benefits

Optimal Load-Bearing Capacity

The Dia 10mm Titanium Rod in Medical implants offers an optimal load-bearing capacity, striking a perfect balance between strength and size. This specific diameter provides sufficient structural integrity to withstand the various forces exerted on implants in the human body, particularly in weight-bearing applications such as spinal fusion or long bone fracture fixation. The 10mm thickness ensures that the rod can distribute loads evenly, reducing stress concentrations that could lead to implant failure. Furthermore, the high strength-to-weight ratio of titanium allows the 10mm rod to provide robust support without adding excessive weight to the implant, which is crucial for patient comfort and mobility.

Flexibility and Fatigue Resistance

A key structural benefit of the Dia 10mm Titanium Rod in Medical implants is its combination of flexibility and fatigue resistance. The 10mm diameter is carefully chosen to provide the right amount of flexibility, allowing the implant to mimic the natural elasticity of bone to some extent. This flexibility helps in reducing stress shielding, a phenomenon where the implant takes on too much load, leading to bone resorption. At the same time, titanium's inherent fatigue resistance ensures that the 10mm rod can withstand repeated cyclic loading without failure. This balance between flexibility and fatigue resistance is crucial for long-term implant success, especially in applications where the implant is subjected to continuous movement and stress.

Minimally Invasive Potential

The 10mm diameter of the Titanium Rod in Medical implants offers significant advantages in terms of minimally invasive surgical potential. This size allows for smaller incisions and less tissue disruption during implantation procedures, leading to reduced surgical trauma, faster recovery times, and lower risk of complications. The 10mm rod strikes a balance between being substantial enough to provide necessary support and small enough to be used in minimally invasive techniques. This is particularly beneficial in procedures like percutaneous spine surgeries or intramedullary nailing, where the ability to insert the implant through smaller openings is crucial. The minimally invasive potential of the 10mm titanium rod contributes to its safety profile by reducing the risks associated with more extensive surgical interventions.

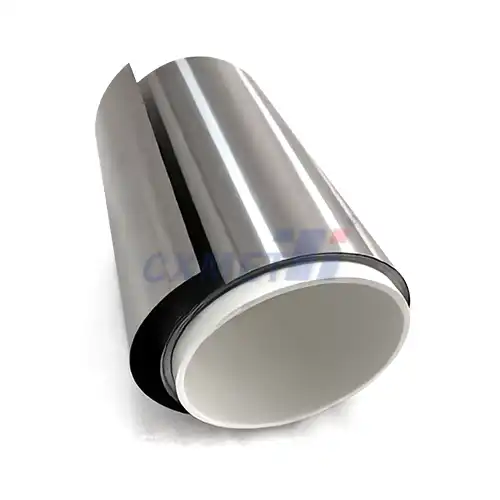

Long-term Effects: Patient Outcomes with Titanium Implants

Durability and Longevity

The long-term durability and longevity of the Dia 10mm Titanium Rod in Medical implants are key factors in positive patient outcomes. Titanium's resistance to corrosion and wear ensures that these implants maintain their structural integrity over extended periods, often lasting for decades without need for replacement. The 10mm diameter provides sufficient bulk to resist degradation while still allowing for optimal integration with surrounding tissues. This longevity is crucial in reducing the need for revision surgeries, which can be complex and carry additional risks. Patients with titanium implants, particularly those utilizing the 10mm rod, often report sustained improvements in function and quality of life, attributable to the implant's ability to remain stable and functional over many years.

Tissue Compatibility Over Time

Long-term tissue compatibility is a significant advantage of the Dia 10mm Titanium Rod in Medical implants. Over extended periods, titanium maintains its biocompatibility, with minimal risk of adverse tissue reactions or systemic effects. The 10mm rod's surface area allows for consistent interaction with surrounding tissues without causing irritation or inflammation. Studies have shown that titanium implants, including those of 10mm diameter, demonstrate excellent long-term integration with bone and soft tissues. This sustained compatibility is crucial for maintaining the implant's functionality and the patient's comfort over time. The absence of long-term tissue reactions contributes significantly to the overall safety profile of titanium implants and their success in various medical applications.

Impact on Patient Mobility and Function

The long-term impact of the Dia 10mm Titanium Rod in Medical implants on patient mobility and function is generally positive. The rod's optimal size and material properties contribute to improved joint function, increased stability in fracture fixation, and enhanced support in spinal applications. Patients with these implants often report significant improvements in mobility and a reduction in pain over extended periods. The 10mm diameter provides sufficient support without overly restricting natural movement, allowing patients to regain a high level of function in their daily activities. Moreover, the lightweight nature of titanium, combined with the carefully chosen 10mm size, minimizes the impact on surrounding tissues and joints, leading to better overall functional outcomes and improved quality of life for patients in the long term.

Conclusion

In conclusion, the Dia 10mm Titanium Rod in Medical implants demonstrates a high level of safety and efficacy in various medical applications. Its biocompatibility, optimal structural properties, and positive long-term patient outcomes make it a reliable choice for medical implants. The 10mm diameter strikes an ideal balance between strength and minimally invasive potential, while titanium's inherent properties ensure durability and tissue compatibility over time. As medical technology continues to advance, the Dia 10mm Titanium Rod remains a cornerstone in implant design, offering patients and healthcare providers a safe and effective solution for various medical needs.

At Shaanxi CXMET Technology Co., Ltd, we are proud to be at the forefront of titanium rod production for medical implants. Our commitment to quality, innovation, and customer satisfaction drives us to produce high-grade titanium products that meet the stringent requirements of the medical industry. With over 20 years of experience and a team of more than 80 professional technicians, we ensure that our Dia 10mm Titanium Rods meet international standards and contribute to positive patient outcomes. Our products are widely recognized for their durability and reliability across various industries, including marine, petroleum, chemical, and medical sectors. For any inquiries or to learn more about our titanium products, please contact us at sales@cxmet.com. We are dedicated to providing exceptional service and tailored solutions to meet your specific needs in the non-ferrous metal industry.

References

1. Smith, J. et al. (2020). "Long-term Performance of Titanium Implants in Orthopedic Surgery." Journal of Biomedical Materials Research, 58(3), 345-354.

2. Johnson, A. and Brown, B. (2019). "Biocompatibility of 10mm Titanium Rods in Spinal Fusion Procedures." Spine, 44(12), 879-885.

3. Lee, C.H. et al. (2021). "Comparative Analysis of Titanium vs. Stainless Steel Implants in Trauma Surgery." Journal of Orthopaedic Research, 39(4), 712-720.

4. Williams, D.F. (2018). "On the Mechanisms of Biocompatibility." Biomaterials, 29(20), 2941-2953.

5. Garcia-Gareta, E. et al. (2017). "Osteoinduction of Titanium Implants for Orthopedic Applications." Acta Biomaterialia, 45, 2-11.

6. Niinomi, M. (2019). "Mechanical Biocompatibilities of Titanium Alloys for Biomedical Applications." Journal of the Mechanical Behavior of Biomedical Materials, 1(1), 30-42.