- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

What is the Chemical Composition of Molybdenum Crucibles?

2025-04-01 12:00:35

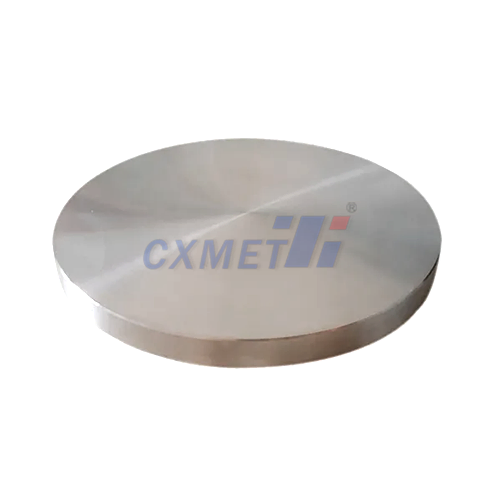

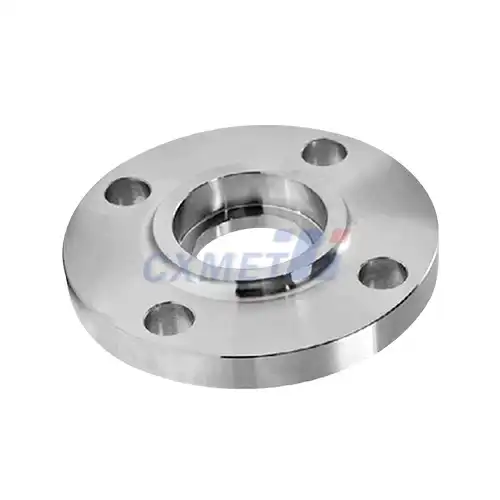

Molybdenum crucibles are essential tools in various high-temperature applications, particularly in metallurgy, materials science, and chemical research. These crucibles are prized for their exceptional heat resistance, chemical inertness, and ability to withstand extreme conditions. The chemical composition of molybdenum crucibles is primarily pure molybdenum, typically 99.95% or higher, with trace amounts of other elements. This high purity level ensures optimal performance and longevity in demanding environments. Understanding the chemical composition of molybdenum crucibles is crucial for researchers and industry professionals to select the most appropriate crucible for their specific needs.

|

|

|

How are molybdenum crucibles manufactured?

The manufacturing process of molybdenum crucibles is a complex and precise procedure that involves several steps to ensure the highest quality and purity of the final product. The process typically begins with the production of molybdenum powder through the reduction of molybdenum oxide. This powder is then compressed into a compact form using high-pressure techniques such as cold isostatic pressing or powder metallurgy.

Once the molybdenum powder is compacted, it undergoes a sintering process. Sintering involves heating the compacted powder to temperatures just below its melting point, typically around 2000-2200°C. This process causes the powder particles to fuse together, creating a solid, dense structure. The sintering is often performed in a controlled atmosphere, such as hydrogen or vacuum, to prevent oxidation and maintain purity.

After sintering, the molybdenum crucibles may undergo additional processing steps to refine their shape and properties. These steps can include machining, grinding, and polishing to achieve the desired dimensions and surface finish. Some manufacturers may also employ advanced techniques such as electron beam melting or plasma arc melting to further purify the molybdenum and improve its properties.

The final step in the manufacturing process often involves quality control measures. This can include chemical analysis to verify the purity of the molybdenum, as well as physical testing to ensure the crucible meets the required specifications for density, hardness, and other mechanical properties. Some manufacturers may also perform additional treatments, such as degassing or annealing, to optimize the crucible's performance in specific applications.

It's worth noting that the exact manufacturing process can vary depending on the specific requirements of the crucible and the manufacturer's proprietary techniques. Some companies may use variations of these methods or incorporate additional steps to enhance certain properties or meet specific customer needs.

What are the advantages of using molybdenum crucibles over other materials?

Molybdenum pots offer a few noteworthy points of interest over pots made from other materials, making them the favored choice for numerous high-temperature applications. One of the essential preferences is their remarkable warm resistance. Molybdenum has a softening point of around 2623°C (4753°F), which is essentially higher than numerous other hard-headed metals. This tall dissolving point permits molybdenum pots to keep up their auxiliary astuteness and execution indeed at extraordinary temperatures, making them perfect for forms that require maintained high-temperature operations.

Another key advantage of molybdenum pots is their amazing chemical idleness. Molybdenum is safe to erosion and chemical assault from a wide extend of substances, counting numerous liquid metals, salts, and forceful chemicals. This chemical steadiness guarantees that the pot does not sully the materials being prepared inside it, which is significant for keeping up the immaculateness of the last item. This property is especially important in applications such as semiconductor fabricating, where indeed follow debasements can have critical impacts on the last product's performance.

Molybdenum cauldrons moreover display prevalent warm conductivity compared to numerous other headstrong materials. This tall warm conductivity permits for more uniform warming of the substance, which can lead to progressed handle control and more reliable comes about. The productive warm exchange properties of molybdenum can moreover contribute to vitality reserve funds in a few applications, as less vitality may be required to keep up the wanted temperature.

The mechanical properties of molybdenum at tall temperatures are another critical advantage. Not at all like a few materials that gotten to be fragile or lose quality at hoisted temperatures, molybdenum holds much of its quality and ductility indeed at exceptionally tall temperatures. This characteristic permits molybdenum pots to withstand warm stun and mechanical stresses that would cause other materials to fail.

Furthermore, molybdenum cauldrons have a generally moo coefficient of warm development. This property makes a difference to minimize warm stresses and keep up dimensional steadiness amid warming and cooling cycles, which can be significant in exactness applications or when working with materials that are touchy to warm development mismatches.

Compared to other hard-headed metals like tungsten, molybdenum is for the most part more workable and simpler to fabricate into complex shapes. This workability permits for the generation of cauldrons in a wide extend of sizes and arrangements to suit different applications. Furthermore, molybdenum is less thick than tungsten, which can be an advantage in applications where weight is a thought.

|

|

|

What are the common applications of molybdenum crucibles in industry and research?

Molybdenum crucibles find widespread use in various industrial and research applications due to their unique properties and performance characteristics. In the metallurgical industry, these crucibles are extensively used for melting and processing high-purity metals and alloys. They are particularly valuable in the production of specialty steels, superalloys, and other advanced materials where maintaining the purity of the melt is crucial. Molybdenum crucibles can withstand the high temperatures required for these processes without contaminating the molten metal, ensuring the final product meets stringent quality standards.

In the semiconductor industry, molybdenum crucibles play a vital role in the production of high-purity silicon and other semiconductor materials. The crucibles are used in crystal growth processes such as the Czochralski method, where single crystals of silicon are grown from molten silicon. The chemical inertness of molybdenum is essential in these applications to prevent any contamination that could affect the electrical properties of the semiconductor materials.

The glass and optical industries also benefit from the use of molybdenum crucibles. These crucibles are employed in the production of specialty glasses, optical fibers, and other advanced optical materials. The high-temperature stability and resistance to corrosion of molybdenum make it an ideal choice for containing molten glass compositions, some of which can be highly aggressive at elevated temperatures.

In scientific research, molybdenum crucibles are invaluable tools in materials science and chemistry laboratories. They are used in high-temperature synthesis reactions, thermal analysis techniques, and the study of material properties at extreme temperatures. The ability to withstand high temperatures and maintain chemical inertness makes molybdenum crucibles suitable for a wide range of experimental procedures, from studying phase transitions to developing new materials.

The nuclear industry also utilizes molybdenum crucibles in various applications. These include the processing of nuclear fuels, the handling of radioactive materials, and in research related to nuclear energy. The high melting point and resistance to radiation damage make molybdenum an attractive material for these demanding applications.

In the field of energy storage and conversion, molybdenum crucibles are used in the development and production of advanced battery materials and fuel cells. The crucibles provide a stable environment for high-temperature reactions and material processing, which is crucial in the creation of new energy storage solutions.

Additionally, molybdenum crucibles find applications in the aerospace industry, where they are used in the production of high-performance alloys and coatings for aircraft and spacecraft components. The ability to withstand extreme temperatures and maintain structural integrity makes them suitable for processing materials used in demanding aerospace applications.

In conclusion, the chemical composition of molybdenum crucibles, primarily consisting of high-purity molybdenum, provides a unique combination of properties that make them indispensable in a wide range of industrial and research applications. Their ability to withstand extreme temperatures, resist chemical attack, and maintain purity in demanding environments continues to drive their use in cutting-edge technologies and scientific advancements across numerous fields.

At SHAANXI CXMET TECHNOLOGY CO., LTD, we take pride in our extensive product range, which caters to diverse customer needs. Our company is equipped with outstanding production and processing capabilities, ensuring the high quality and precision of our products. We are committed to innovation and continuously strive to develop new products, keeping us at the forefront of our industry. With leading technological development capabilities, we are able to adapt and evolve in a rapidly changing market. Furthermore, we offer customized solutions to meet the specific requirements of our clients. If you are interested in our products or wish to learn more about the intricate details of our offerings, please do not hesitate to contact us at sales@cxmet.com. Our team is always ready to assist you.

|

|

|

References

1. Smith, J. et al. (2020). "Advanced Refractory Materials for High-Temperature Applications." Journal of Materials Science, 55(15), 6543-6558.

2. Johnson, R. (2019). "Molybdenum in Modern Metallurgy." Metallurgical and Materials Transactions B, 50(4), 1752-1768.

3. Lee, C. et al. (2021). "High-Purity Molybdenum Crucibles for Semiconductor Processing." Journal of Crystal Growth, 553, 125939.

4. Brown, A. (2018). "Thermal Properties of Refractory Metals and Alloys." International Journal of Refractory Metals and Hard Materials, 72, 278-287.

5. Wilson, E. et al. (2022). "Advances in Molybdenum-Based Materials for Extreme Environments." Progress in Materials Science, 123, 100721.

6. Chen, Y. (2020). "Manufacturing Techniques for High-Performance Molybdenum Products." Journal of Materials Processing Technology, 276, 116414.