- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Why is Titanium AMS 6242 Rod preferred for critical aerospace applications?

2025-04-14 16:30:17

Titanium AMS 6242 Rod For Aerospace has become a preferred material for critical aerospace applications due to its exceptional combination of properties. This high-performance titanium alloy offers an ideal balance of strength, lightweight characteristics, and corrosion resistance, making it particularly suitable for demanding aerospace environments. As the aerospace industry continually seeks materials that can withstand extreme conditions while minimizing weight, Titanium AMS 6242 Rod has emerged as a go-to solution for various critical components in aircraft and spacecraft.

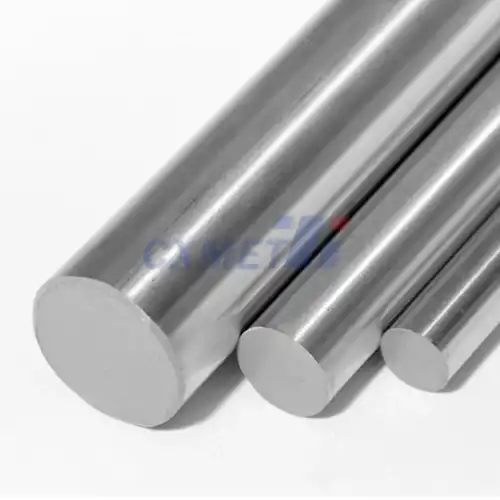

|

|

|

What are the key properties that make Titanium AMS 6242 Rod ideal for aerospace use?

Titanium AMS 6242 Rod For Aerospace possesses a unique set of properties that make it exceptionally well-suited for aerospace applications. First and foremost, its high strength-to-weight ratio is a critical factor in its popularity. This alloy offers excellent mechanical strength while being significantly lighter than many other metals used in aerospace, such as steel. The weight reduction achieved by using Titanium AMS 6242 Rod translates directly into fuel savings and increased payload capacity for aircraft and spacecraft.

Another key property of Titanium AMS 6242 Rod is its outstanding corrosion resistance. In the harsh environments encountered during flight, including exposure to various chemicals, fuels, and atmospheric conditions, this alloy maintains its integrity and performance. This corrosion resistance not only ensures the longevity of components but also reduces maintenance requirements and enhances overall safety.

The alloy's ability to maintain its strength at elevated temperatures is another crucial factor. Aerospace applications often involve exposure to high temperatures, particularly in engine components or structures near heat sources. Titanium AMS 6242 Rod retains its mechanical properties at temperatures up to 1000°F (538°C), making it suitable for use in areas where other materials might fail or degrade.

Furthermore, Titanium AMS 6242 Rod exhibits excellent fatigue resistance. In aerospace applications, materials are subjected to repeated stress cycles, and fatigue failure is a significant concern. The superior fatigue properties of this alloy ensure that components can withstand the cyclic loading experienced during flight operations, contributing to the overall reliability and safety of aerospace structures.

The alloy's low thermal expansion coefficient is another advantage in aerospace applications. This property minimizes dimensional changes due to temperature fluctuations, which is crucial for maintaining precise tolerances in aerospace components. Additionally, Titanium AMS 6242 Rod offers good weldability and machinability, facilitating the manufacturing and assembly processes of complex aerospace parts.

How does Titanium AMS 6242 Rod compare to other aerospace materials in terms of performance?

When comparing Titanium AMS 6242 Rod For Aerospace to other aerospace materials, its performance stands out in several key areas. One of the primary competitors in aerospace applications is aluminum alloys, which have been widely used due to their lightweight properties. However, Titanium AMS 6242 Rod offers superior strength-to-weight ratio compared to most aluminum alloys. While aluminum is lighter, titanium's higher strength allows for the use of less material, often resulting in a net weight reduction for structural components.

In comparison to steel alloys, which are known for their high strength, Titanium AMS 6242 Rod offers comparable strength at a significantly lower weight. This weight reduction is crucial in aerospace applications where every pound saved translates to improved fuel efficiency and increased payload capacity. Additionally, titanium's superior corrosion resistance gives it an edge over steel in many aerospace environments, particularly in areas exposed to harsh conditions or corrosive substances.

When it comes to high-temperature applications, Titanium AMS 6242 Rod outperforms many other materials. While some nickel-based superalloys can operate at higher temperatures, they are often much heavier than titanium. The ability of Titanium AMS 6242 Rod to maintain its strength at elevated temperatures, combined with its lower density, makes it an ideal choice for components that require both heat resistance and weight savings.

In terms of fatigue resistance, Titanium AMS 6242 Rod performs exceptionally well compared to many other aerospace materials. Its fatigue strength is superior to that of aluminum alloys and comparable to or better than many steel alloys. This property is particularly important in aerospace applications where components are subjected to cyclic loading over extended periods.

The corrosion resistance of Titanium AMS 6242 Rod is another area where it outperforms many competing materials. Unlike steel, which requires protective coatings or treatments to prevent corrosion in aerospace environments, titanium naturally forms a stable, protective oxide layer. This inherent corrosion resistance reduces maintenance requirements and extends the service life of components, providing long-term cost benefits.

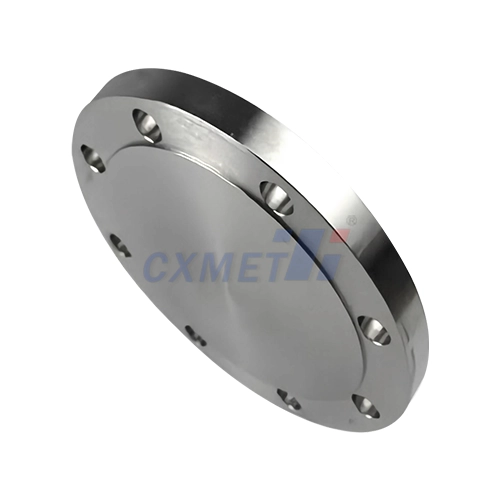

|

|

|

What specific aerospace components are commonly manufactured using Titanium AMS 6242 Rod?

Titanium AMS 6242 Rod For Aerospace is used in a wide range of aerospace components, leveraging its unique properties to enhance performance and reliability. One of the most common applications is in aircraft engine components. The alloy's high strength-to-weight ratio and heat resistance make it ideal for fan blades, compressor blades, and other engine parts that operate under high stress and temperature conditions. These components benefit from the material's ability to withstand the extreme forces and temperatures encountered during flight while contributing to overall engine efficiency through weight reduction.

In airframe structures, Titanium AMS 6242 Rod is often used for critical load-bearing components. This includes parts of the fuselage, wing structures, and landing gear components. The material's high strength allows for the design of thinner, lighter structures that can still withstand the significant loads experienced during flight and landing. Additionally, its fatigue resistance ensures the longevity of these components, which are subjected to repeated stress cycles throughout the aircraft's operational life.

Hydraulic and pneumatic systems in aircraft also frequently utilize components made from Titanium AMS 6242 Rod. The alloy's corrosion resistance is particularly valuable in these applications, where exposure to various fluids is common. Pump housings, valve bodies, and actuator components are often manufactured using this material, taking advantage of its strength and resistance to degradation in challenging environments.

In spacecraft and satellite applications, Titanium AMS 6242 Rod finds use in structural components and propulsion systems. The material's low density is crucial in these applications, where every gram of weight impacts launch costs and fuel requirements. Satellite frames, support structures for solar panels, and components of thruster systems often incorporate this alloy to achieve the necessary strength while minimizing overall mass.

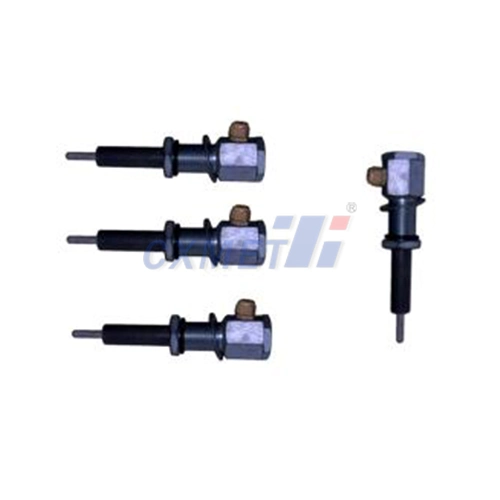

Another important application is in fasteners and connectors used throughout aerospace structures. The combination of strength, corrosion resistance, and fatigue resistance makes Titanium AMS 6242 Rod an excellent choice for bolts, nuts, and other fastening components that play a critical role in holding aerospace structures together. These fasteners must maintain their integrity under a wide range of environmental conditions and loading scenarios.

In conclusion, Titanium AMS 6242 Rod For Aerospace has established itself as a crucial material in the aerospace industry due to its exceptional combination of properties. Its high strength-to-weight ratio, corrosion resistance, and ability to perform in extreme conditions make it ideal for a wide range of critical aerospace applications. From engine components to structural elements and fasteners, this alloy continues to play a vital role in advancing aerospace technology and improving the performance and efficiency of aircraft and spacecraft.

At SHAANXI CXMET TECHNOLOGY CO., LTD, we take pride in our extensive product range, which caters to diverse customer needs. Our company is equipped with outstanding production and processing capabilities, ensuring the high quality and precision of our products. We are committed to innovation and continuously strive to develop new products, keeping us at the forefront of our industry. With leading technological development capabilities, we are able to adapt and evolve in a rapidly changing market. Furthermore, we offer customized solutions to meet the specific requirements of our clients. If you are interested in our products or wish to learn more about the intricate details of our offerings, please do not hesitate to contact us at sales@cxmet.com. Our team is always ready to assist you.

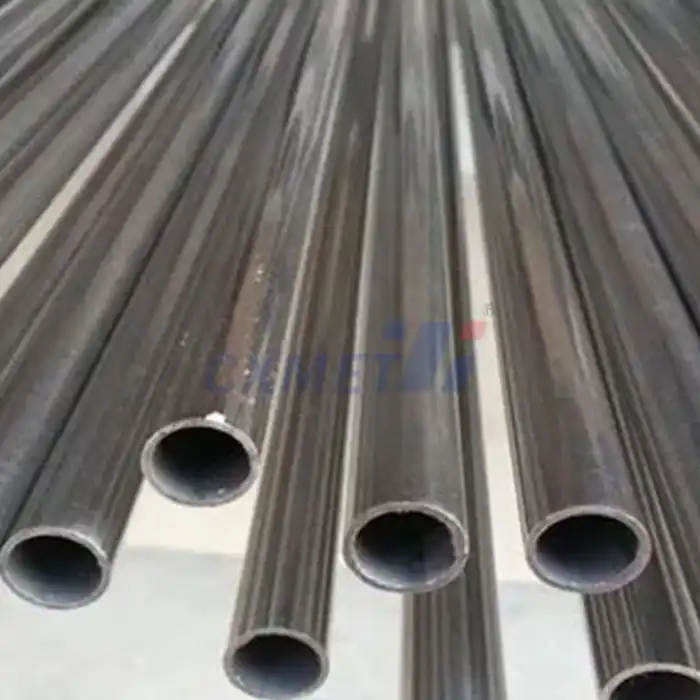

|

|

|

References

- ASM International. (2015). Titanium: A Technical Guide, 2nd Edition.

- Boyer, R., Welsch, G., & Collings, E. W. (1994). Materials Properties Handbook: Titanium Alloys. ASM International.

- Leyens, C., & Peters, M. (Eds.). (2003). Titanium and Titanium Alloys: Fundamentals and Applications. John Wiley & Sons.

- Peters, M., Kumpfert, J., Ward, C. H., & Leyens, C. (2003). Titanium alloys for aerospace applications. Advanced Engineering Materials, 5(6), 419-427.

- Donachie, M. J. (2000). Titanium: A Technical Guide, 2nd Edition. ASM International.

- Inagaki, I., Takechi, T., Shirai, Y., & Ariyasu, N. (2014). Application and features of titanium for the aerospace industry. Nippon Steel & Sumitomo Metal Technical Report, 106, 22-27.

- Boyer, R. R. (1996). An overview on the use of titanium in the aerospace industry. Materials Science and Engineering: A, 213(1-2), 103-114.

- Williams, J. C., & Starke Jr, E. A. (2003). Progress in structural materials for aerospace systems. Acta Materialia, 51(19), 5775-5799.

- Lutjering, G., & Williams, J. C. (2007). Titanium. Springer Science & Business Media.

- Mouritz, A. P. (2012). Introduction to aerospace materials. Elsevier.