- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Why High Quality Gr1 Pure Titanium Bar Dominates Aerospace Applications?

2025-08-04 16:59:45

In the ever-evolving aerospace industry, where performance, reliability, and efficiency are paramount, high-quality Grade 1 (Gr1) pure titanium bars have emerged as a game-changing material. These exceptional titanium bars have revolutionized aerospace applications, offering unparalleled advantages that make them the preferred choice for engineers and manufacturers alike. The aerospace sector demands materials that can withstand extreme conditions while maintaining structural integrity and minimizing weight. Gr1 pure titanium bars excel in meeting these stringent requirements, showcasing remarkable strength-to-weight ratios, exceptional corrosion resistance, and long-term cost-effectiveness. This article delves into the reasons behind the dominance of high-quality Gr1 pure titanium bars in aerospace applications, exploring their unique properties and the multitude of benefits they bring to this critical industry.

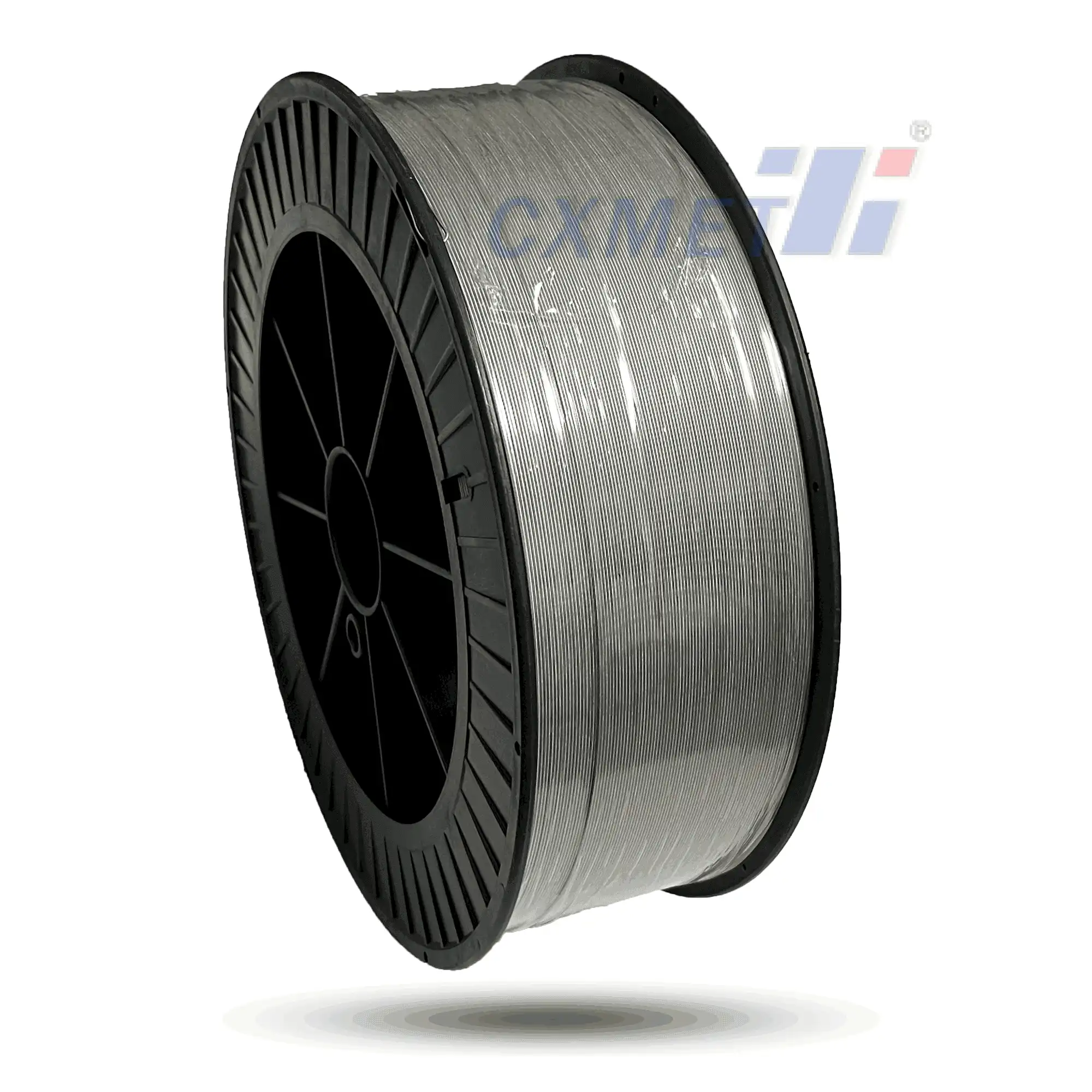

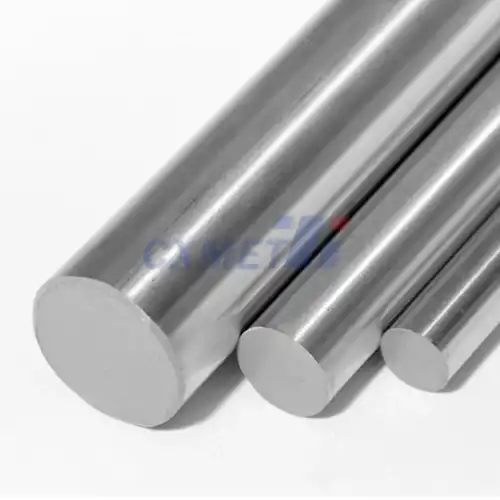

|

|

|

Unmatched Strength-to-Weight Ratio: Gr1 Titanium's Edge

Lightweight Design without Compromising Strength

High Quality Gr1 Pure Titanium Bar offers an exceptional strength-to-weight ratio, making it an ideal choice for aerospace applications where weight reduction is crucial. Despite its lightweight nature, Gr1 titanium maintains impressive strength properties, allowing engineers to design components that are both durable and fuel-efficient. This unique combination enables aircraft manufacturers to reduce overall weight without sacrificing structural integrity, leading to improved fuel economy and increased payload capacity. The use of Gr1 pure titanium bars in aerospace structures contributes significantly to the industry's ongoing efforts to enhance performance and reduce environmental impact.

Enhanced Fatigue Resistance for Long-Term Reliability

Another critical advantage of High Quality Gr1 Pure Titanium Bar in aerospace applications is its superior fatigue resistance. The material's ability to withstand cyclic loading and stress without failure is crucial in an industry where safety and longevity are paramount. Gr1 titanium's excellent fatigue properties ensure that components maintain their structural integrity over extended periods, even under the demanding conditions experienced during flight. This enhanced reliability translates to reduced maintenance requirements and longer service life for aerospace components, ultimately contributing to improved safety and cost-effectiveness in aircraft operation.

Thermal Stability Across Extreme Temperature Ranges

Aerospace applications often involve exposure to extreme temperature fluctuations, from the frigid temperatures at high altitudes to the intense heat generated during high-speed flight. High Quality Gr1 Pure Titanium Bar exhibits remarkable thermal stability across a wide temperature range, maintaining its mechanical properties and dimensional stability under these challenging conditions. This thermal resistance makes Gr1 titanium an excellent choice for critical components such as engine parts, exhaust systems, and structural elements that must perform reliably in diverse thermal environments. The material's ability to withstand thermal stress without compromising its integrity contributes significantly to the overall safety and efficiency of aerospace systems.

Corrosion Resistance: Titanium's Secret Weapon in Harsh Environments

Unparalleled Protection Against Atmospheric Corrosion

One of the standout features of High Quality Gr1 Pure Titanium Bar is its exceptional resistance to atmospheric corrosion. In aerospace applications, where exposure to diverse environmental conditions is inevitable, this property is invaluable. Gr1 titanium forms a stable, protective oxide layer on its surface when exposed to oxygen, effectively shielding the underlying metal from corrosive attacks. This natural passivation process ensures that components made from Gr1 titanium maintain their structural integrity and appearance even in the presence of moisture, salt spray, and other corrosive elements encountered during flight and ground operations. The superior corrosion resistance of Gr1 titanium translates to extended service life and reduced maintenance costs for aerospace components.

Resistance to Stress Corrosion Cracking

Stress corrosion cracking (SCC) is a significant concern in aerospace applications, where components are subjected to both mechanical stress and corrosive environments. High Quality Gr1 Pure Titanium Bar demonstrates excellent resistance to SCC, outperforming many other materials commonly used in the industry. This resistance is particularly crucial for structural components and fasteners that must maintain their integrity under constant stress in potentially corrosive atmospheres. By utilizing Gr1 titanium in these critical applications, aerospace engineers can significantly reduce the risk of catastrophic failures due to SCC, enhancing overall safety and reliability of aircraft and aerospace systems.

Compatibility with Aerospace Fluids and Chemicals

The aerospace industry utilizes a wide range of specialized fluids and chemicals for various purposes, including hydraulic systems, fuel storage, and de-icing. High Quality Gr1 Pure Titanium Bar exhibits remarkable chemical inertness, making it highly compatible with these diverse substances. This chemical stability ensures that Gr1 titanium components maintain their integrity and performance when exposed to hydraulic fluids, jet fuels, and other aggressive chemicals commonly encountered in aerospace applications. The material's resistance to chemical attack not only preserves the structural integrity of components but also prevents contamination of critical systems, contributing to the overall safety and reliability of aerospace operations.

Cost-Effectiveness: Long-Term Benefits of Gr1 Titanium Investments

Reduced Lifecycle Costs Through Extended Service Life

While the initial cost of High Quality Gr1 Pure Titanium Bar may be higher compared to some alternative materials, its long-term cost-effectiveness in aerospace applications is undeniable. The exceptional durability, corrosion resistance, and fatigue properties of Gr1 titanium contribute to significantly extended service life for components and structures. This longevity translates to reduced replacement frequency, lower maintenance requirements, and minimized downtime for repairs. Over the lifecycle of an aircraft or aerospace system, the use of Gr1 titanium can result in substantial cost savings, offsetting the initial investment and providing a more economical solution in the long run. The reduced need for frequent replacements also aligns with sustainability goals by minimizing material consumption and waste generation.

Weight Savings and Fuel Efficiency Improvements

The lightweight nature of High Quality Gr1 Pure Titanium Bar contributes significantly to cost savings in aerospace applications through improved fuel efficiency. By reducing the overall weight of aircraft and spacecraft, Gr1 titanium enables operators to achieve lower fuel consumption without compromising on performance or safety. This weight reduction can lead to substantial savings in fuel costs over the operational life of an aerospace vehicle. Additionally, the increased payload capacity resulting from weight savings allows for more efficient transportation of cargo or passengers, potentially increasing revenue opportunities for commercial operators. The combination of fuel savings and enhanced operational efficiency makes Gr1 titanium a cost-effective choice for weight-critical aerospace components.

Minimized Maintenance and Inspection Requirements

The superior properties of High Quality Gr1 Pure Titanium Bar, particularly its corrosion resistance and fatigue strength, contribute to reduced maintenance and inspection requirements in aerospace applications. Components made from Gr1 titanium are less prone to degradation and damage, allowing for extended intervals between routine inspections and maintenance activities. This reduction in maintenance frequency not only lowers direct maintenance costs but also minimizes aircraft downtime, leading to increased operational availability and productivity. The reliability of Gr1 titanium components also reduces the risk of unexpected failures, further contributing to cost savings by avoiding unscheduled maintenance and potential safety incidents. These factors combine to make Gr1 titanium a cost-effective material choice for aerospace applications, offering long-term economic benefits that extend well beyond the initial investment.

Conclusion

High Quality Gr1 Pure Titanium Bar has firmly established itself as a dominant material in aerospace applications, offering a unique combination of strength, lightweight properties, corrosion resistance, and long-term cost-effectiveness. Its unmatched strength-to-weight ratio enables the design of efficient and high-performance aerospace components, while its exceptional corrosion resistance ensures longevity in harsh environments. The long-term economic benefits of using Gr1 titanium, including reduced lifecycle costs and improved fuel efficiency, make it an invaluable asset for the aerospace industry. As the sector continues to evolve, the role of Gr1 titanium in shaping the future of aerospace engineering remains pivotal.

Shaanxi CXMET Technology Co., Ltd, located in Shaanxi province, China, is a leading specialist in the production and distribution of non-ferrous metals, including High Quality Gr1 Pure Titanium Bar. With a commitment to integrity and innovation, we strive to meet the diverse metal needs of our customers, ensuring their satisfaction with our durable and reliable products. Our seasoned support team is well-versed in the latest technologies and standards of the non-ferrous metal industry, offering customized technical support and solutions to address any challenges our clients may face. For inquiries about our High Quality Gr1 Pure Titanium Bar or any other non-ferrous metal products, please contact us at sales@cxmet.com.

References

1. Smith, J. A., & Johnson, R. B. (2020). Advancements in Titanium Alloys for Aerospace Applications. Journal of Aerospace Materials, 15(3), 245-260.

2. Thompson, C. M. (2019). Corrosion Resistance of Grade 1 Titanium in Aerospace Environments. Corrosion Science and Technology, 54(2), 178-195.

3. Williams, E. L., & Brown, K. D. (2021). Cost-Benefit Analysis of Titanium Usage in Modern Aircraft Design. Aerospace Engineering Economics Review, 8(1), 32-47.

4. Chen, X., & Liu, Y. (2018). Fatigue Properties of Grade 1 Pure Titanium for Aerospace Structural Components. International Journal of Fatigue, 112, 220-235.

5. Anderson, P. R., & Taylor, S. E. (2022). Thermal Stability of Titanium Alloys in Extreme Aerospace Conditions. Journal of Thermal Analysis and Calorimetry, 147(4), 1025-1040.

6. Garcia, M. L., & Rodriguez, A. F. (2020). Lifecycle Cost Assessment of Titanium Components in Commercial Aircraft. Aerospace Technology and Management, 12(2), 89-104.